All Activity

- Past hour

-

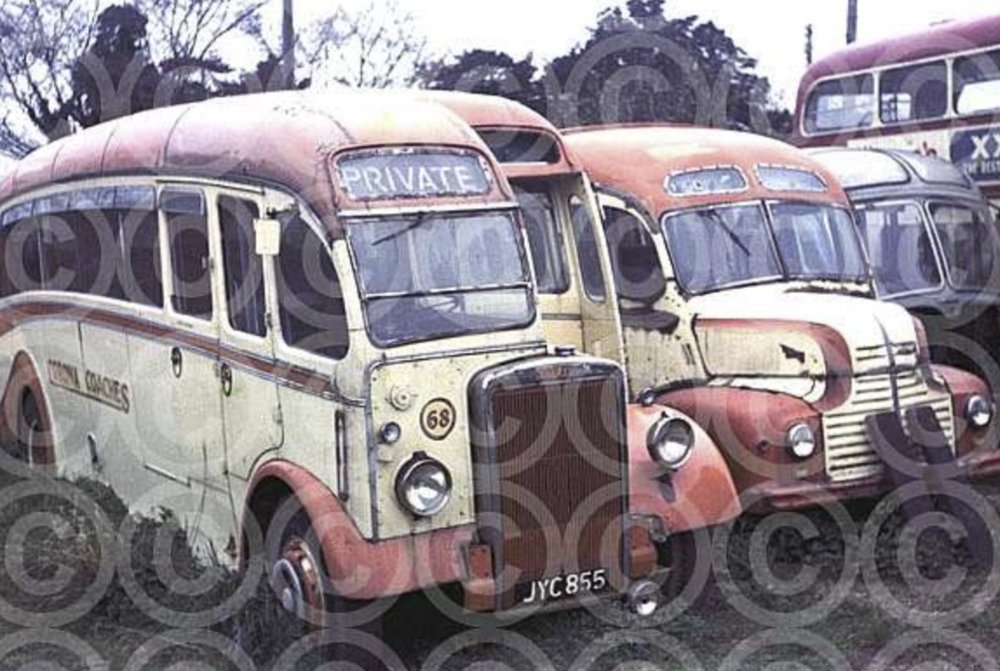

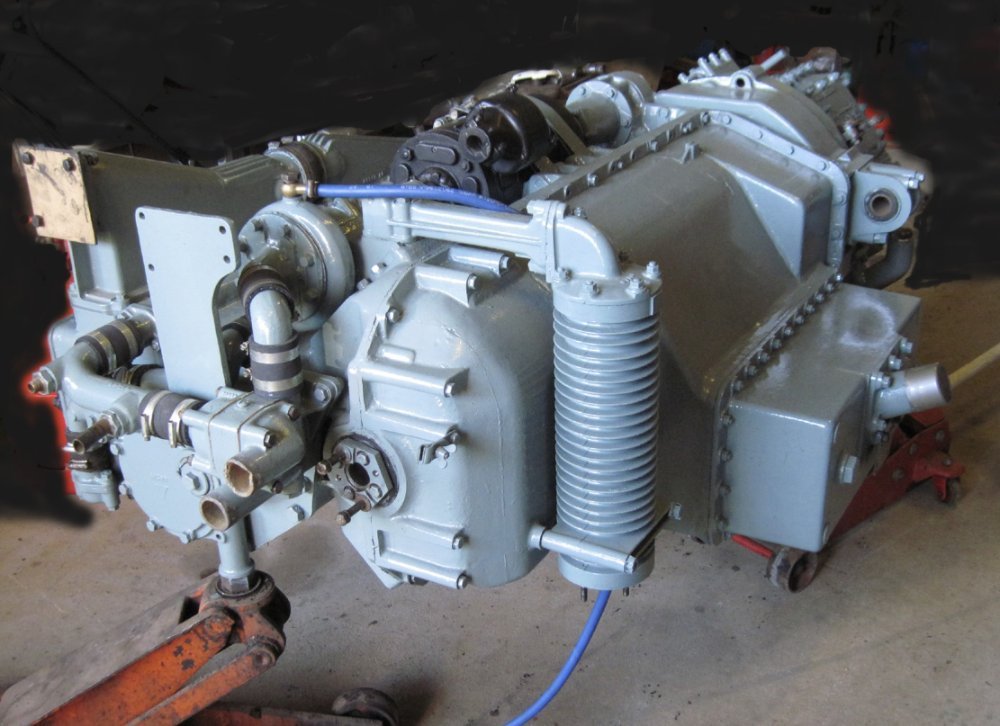

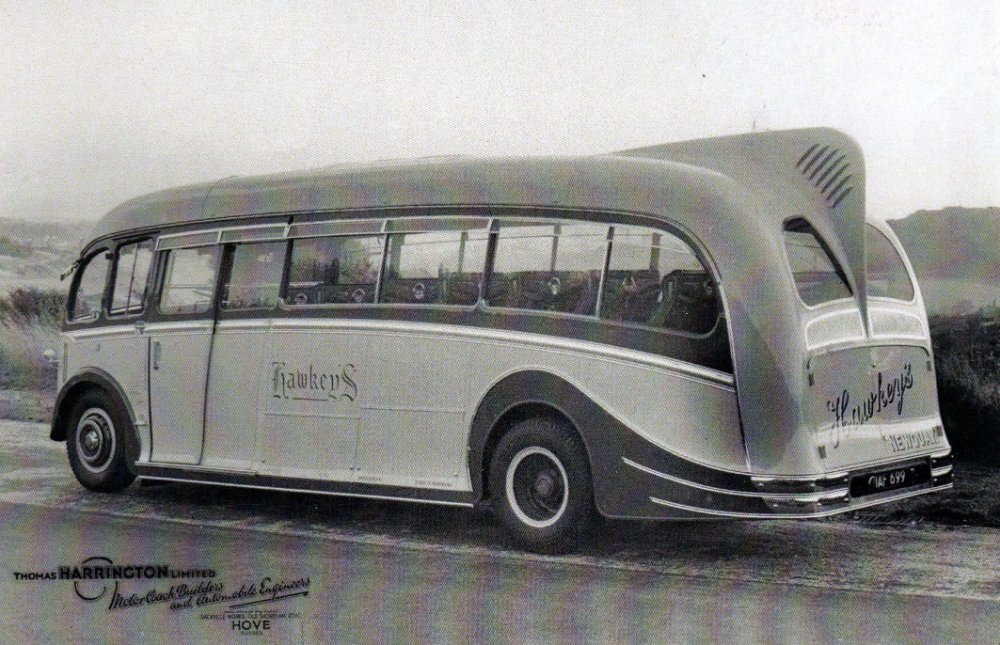

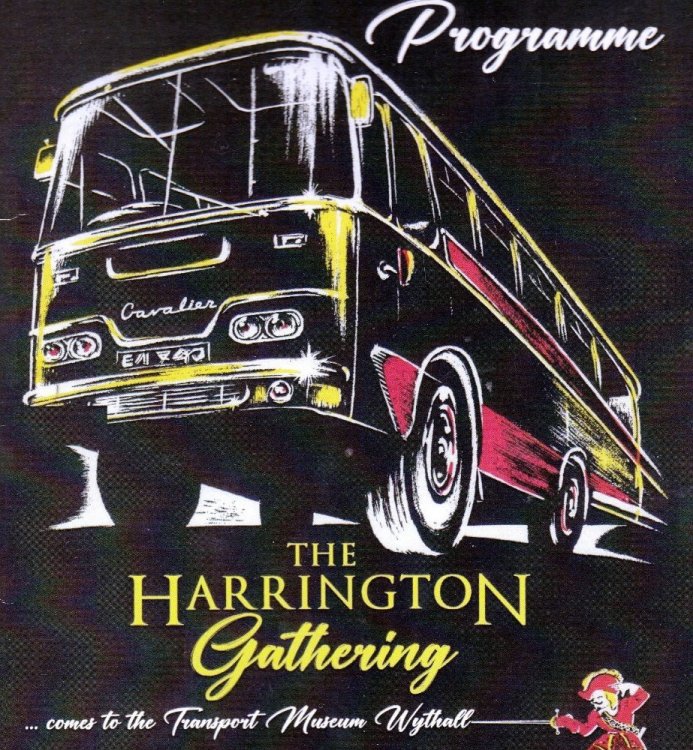

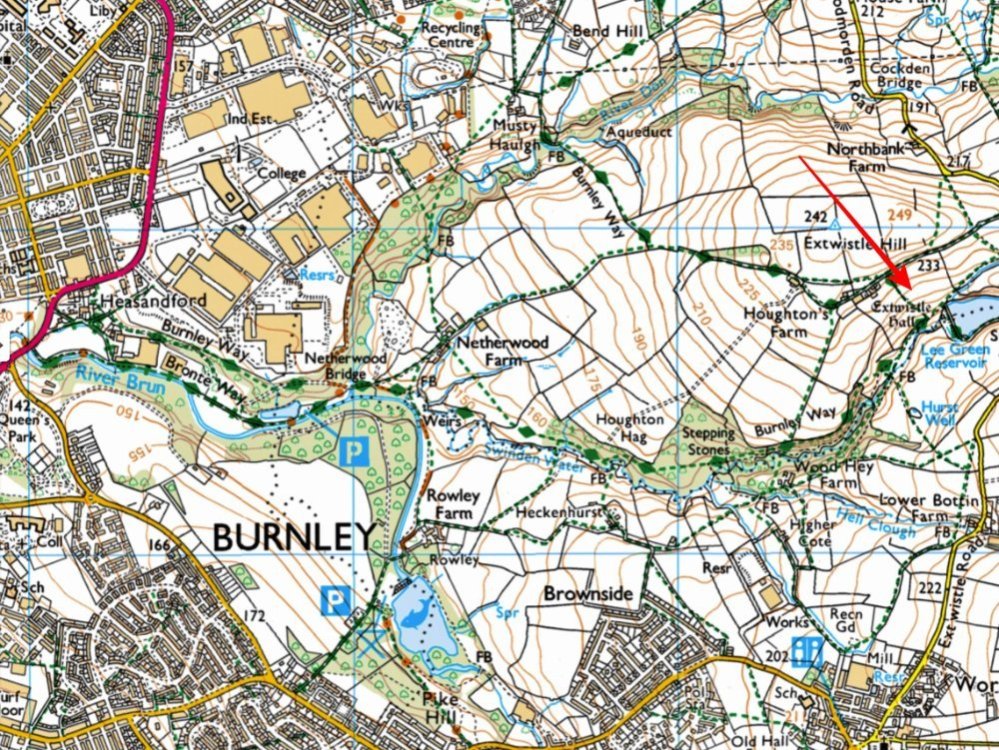

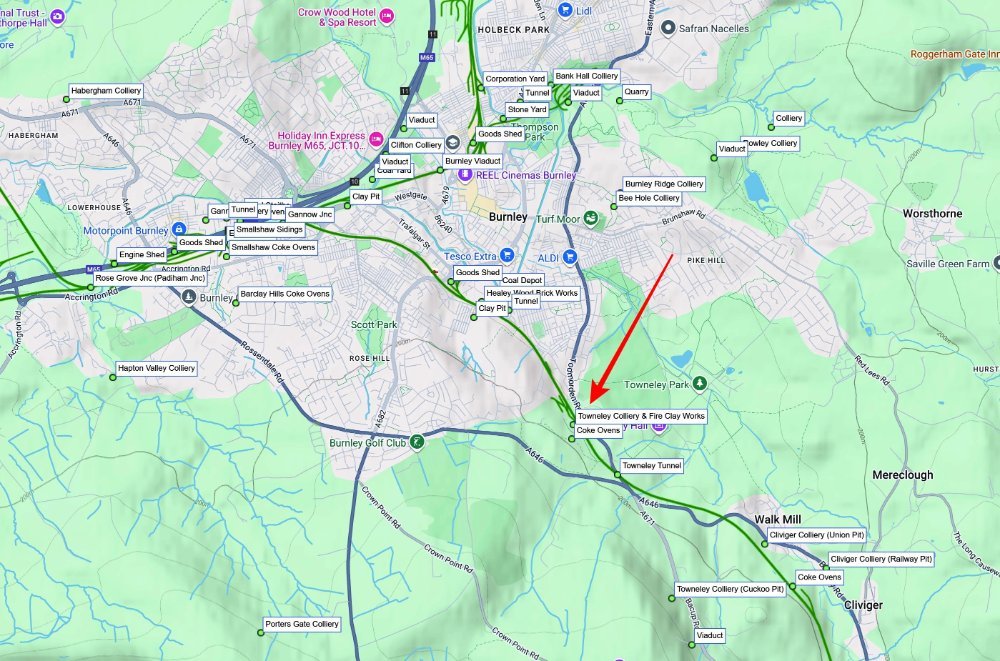

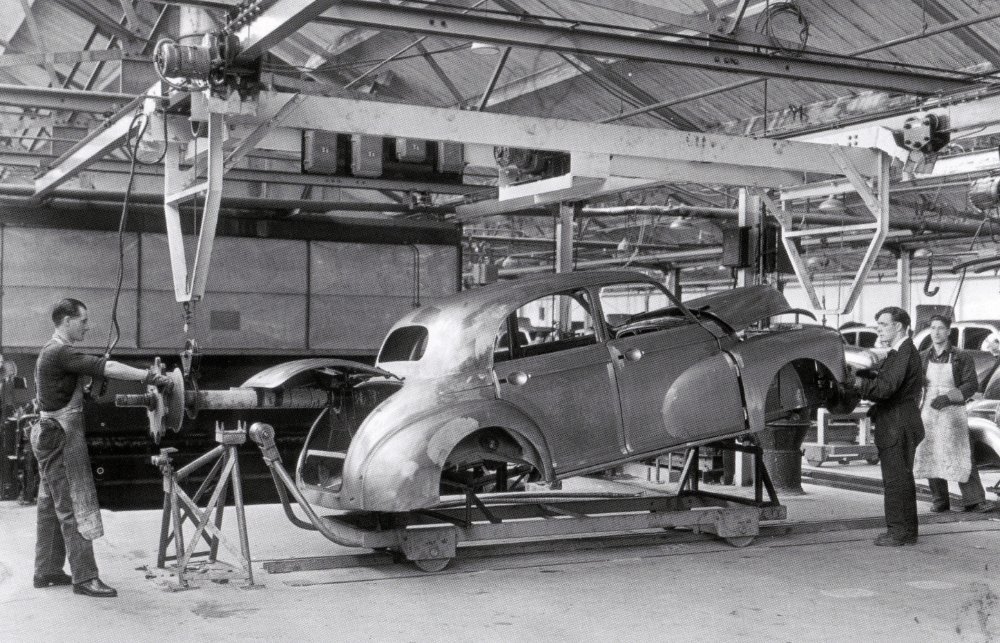

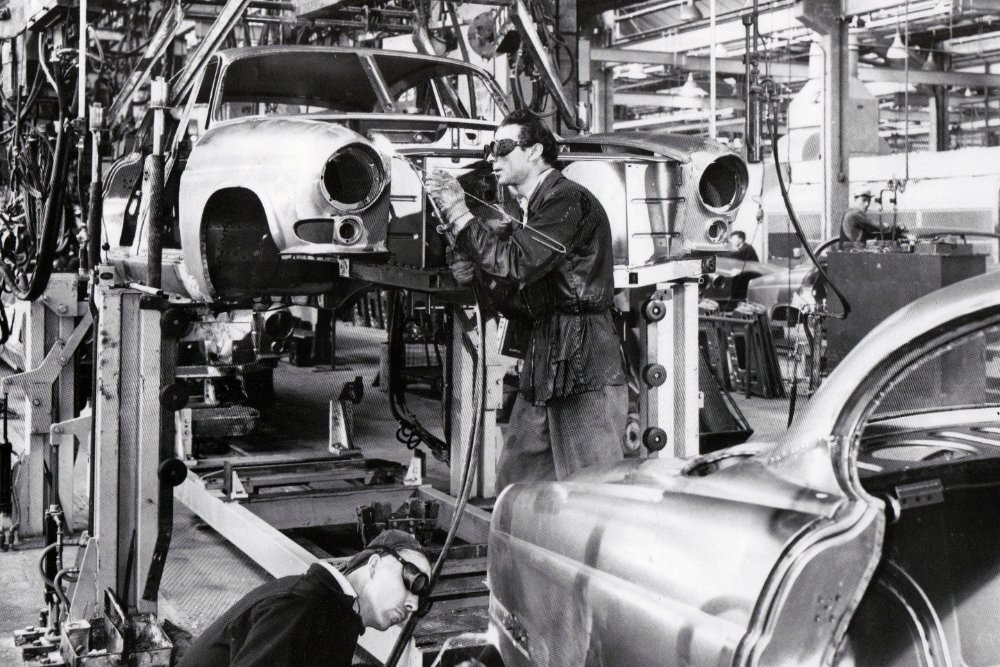

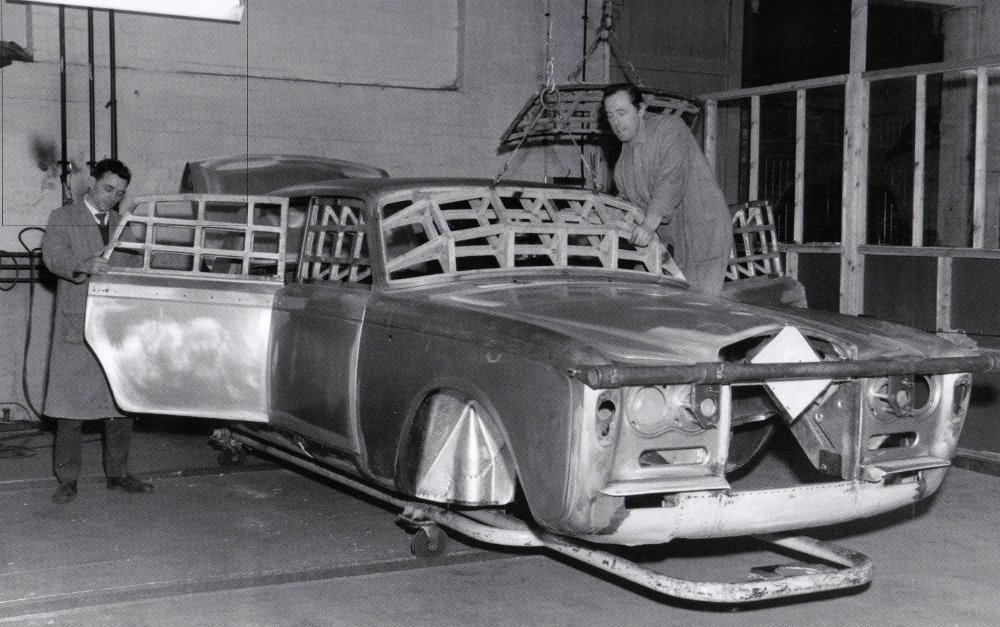

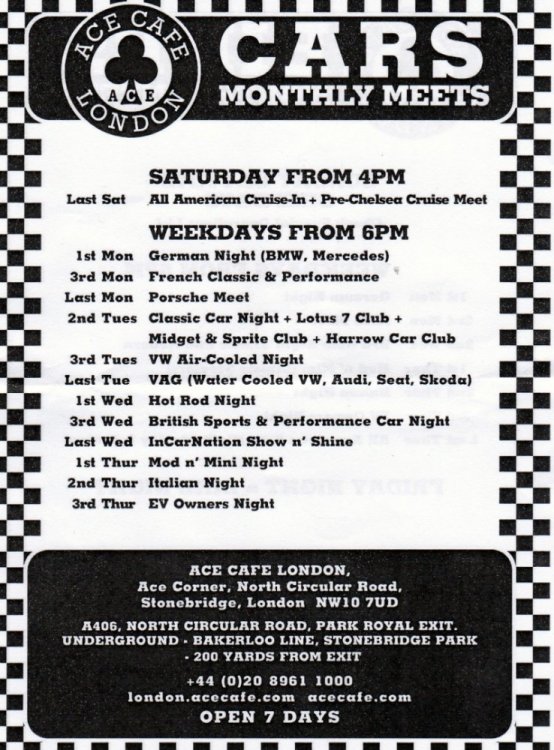

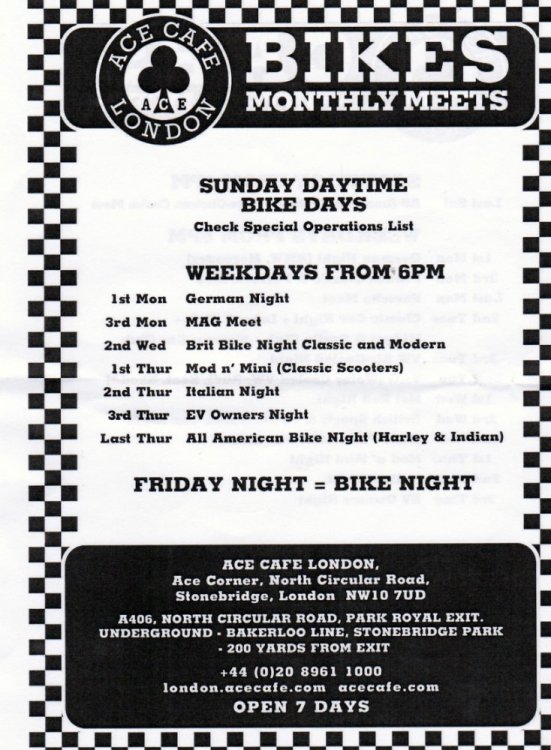

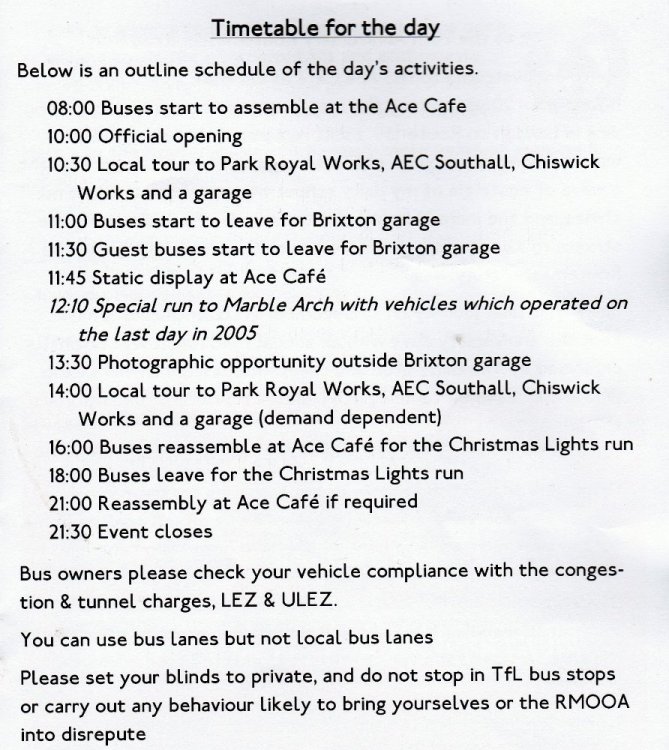

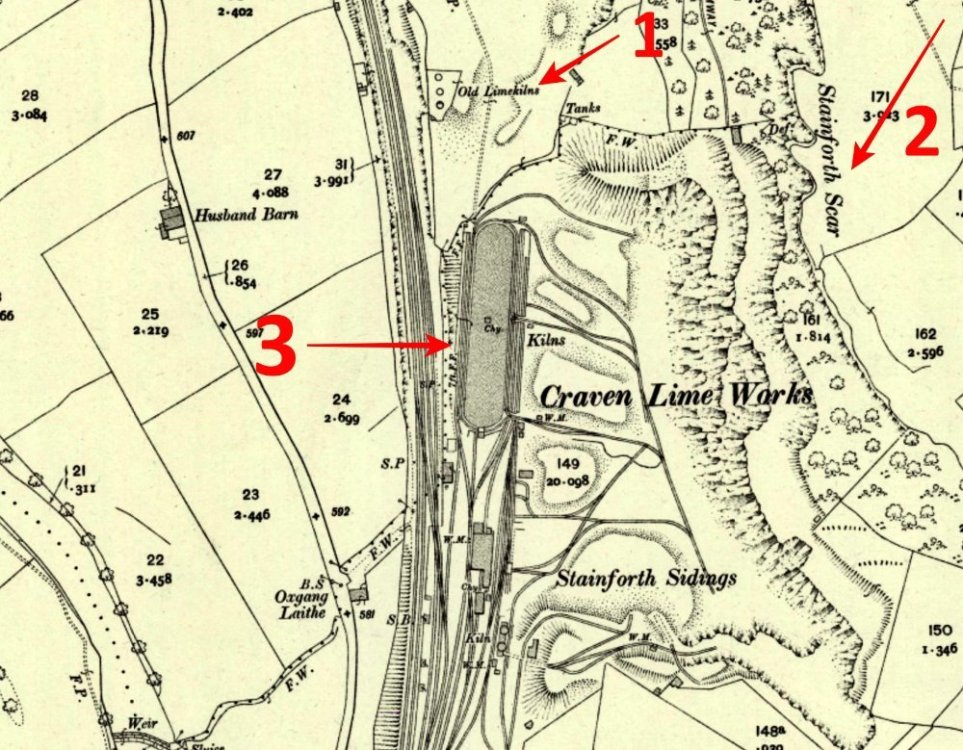

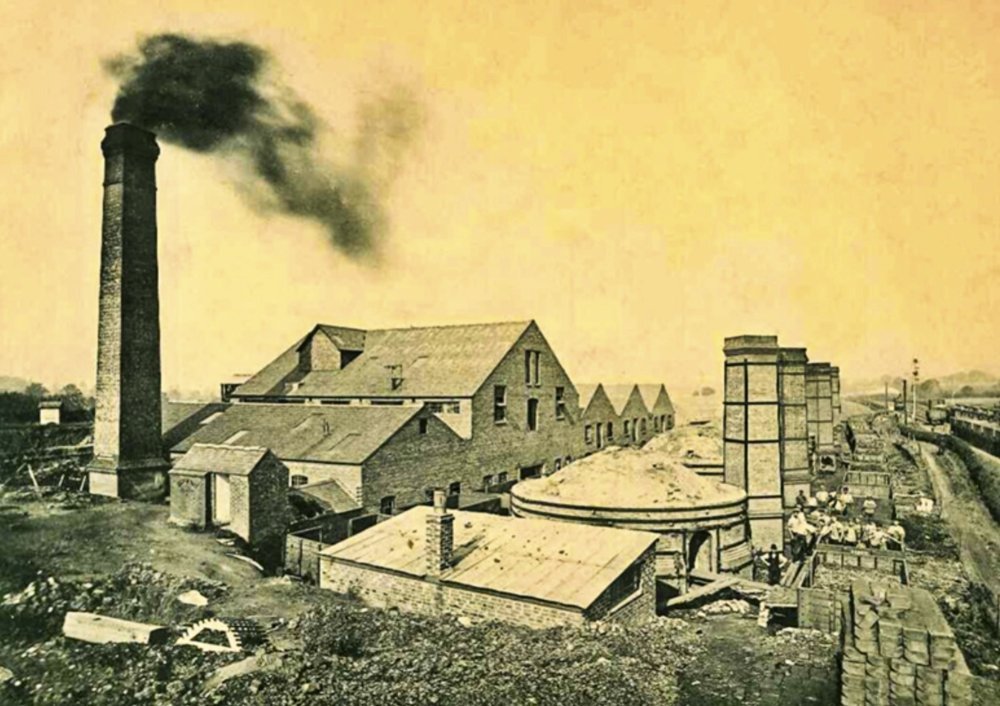

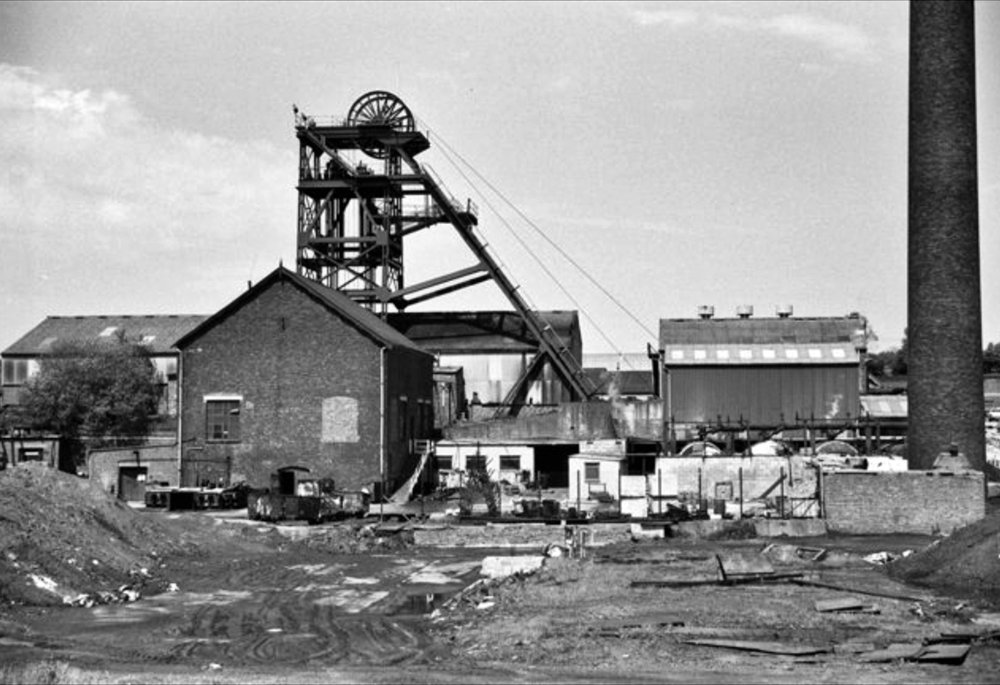

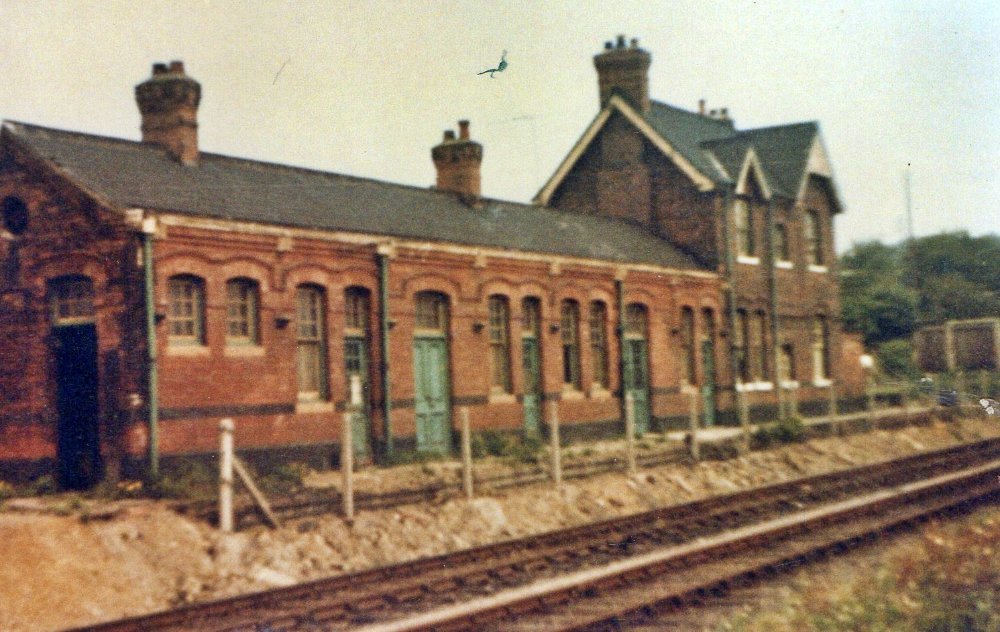

Hi there folks. Welcome to episode 3. In this one: Section 1: F2 pics from Aldershot & Knockhill Section 2: Out and About 1 – The Harrington Gathering Out and About 2 - Extwistle Hall Odds and Ends – London Transport posters, the Pressed Steel Company of Great Britain, Routemasters on the 159 Run. Section 1 Aldershot - Sunday May 18th 2025 - WCQR 43 cars on hand for this WCQR: The DLRD Volvo FL618 is coming up for 30yrs old The Burgoyne Scania is always immaculate Gordon had been racing at King’s Lynn the previous evening On the Phil Mann wing Jessica Smith – Rebecca in front won Heat 2 Josh Weare Ryan McGill in the ex-183 car scored two victories Charlie Guinchard The Philp Scania A 20yr old beauty Charlie Lobb needed some repairs to the front corner after his first race George MacMillan Jnr Kasey Jones Craig Wallace Aidan Grindey had some repairs to do on the front corner after crashing out of the Final Reece Winch won the Final Heat 1 463 514 213 155 543 569 390 629 16 239 Heat 2 931 915 183 7 674 100 667 186 578 411 Consolation 355 12 776 895 821 285 903 8 223 315 542 53 Final 411 16 7 915 213 390 569 667 183 674 GN 463 915 569 514 667 100 7 183 315 155 Knockhill – Wednesday June 18th 2025 The first of the two Wednesday evening meetings for the F2s drew a large crowd. It was Team Burgoyne all the way as they won three out of the four races. The magnificent transporters and cars of Team Burgoyne Brian Hogg had a run out in John’s car Paul Moffatt – Troy the Plumber Graeme Leckie’s very smart WRC#95 Relatively local lad Reece McIntosh Adrian Finnegan from Downpatrick NI Ray Weldon – Chester-Le-Street Drivetrain work on the 7 car The top 3 in the Final 3rd place takes 1st & 2nd around on the victory lap The next meeting here would not see such friendliness between 7 and 647 however! Heat 1 647 514 463 7 674 547 402 16 213 100 Heat 2 647 7 674 100 463 16 213 514 629 402 Final 674 647 7 100 16 463 514 387 213 629 GN 514 100 463 647 7 16 547 629 213 402 Section 2 Out and About 1 The Harrington Gathering Harrington was the most fondly respected coachbuilder of the 20th century. To celebrate this roughly every five years there is a ‘Harrington Gathering’. It all started back in 1986, a mere 20 years since the last Harrington product – a Grenadier-bodied AEC Reliance – left Sackville works to join the long-established fleet of Greenslades Tours of Exeter, Devon. Even back then, there was a feeling of loss with respect to the Hove based coachbuilder. The mention of a Harrington product brings back memories to many people. From the iconic ‘Dorsal Fin’, to going on holiday on a coach belonging to one of the operators who staunchly supported the coachbuilder for decades – such as Maidstone & District or Southdown. The history of the company: In 1897 Thomas Harrington (1859-1928) started building light horse drawn passenger wagonettes, flys, and landaus at his premises in Church Street, Brighton. Within three years the original works was expanded, and new showrooms were acquired in King Street. The increasing popularity of the motor car meant that this became the mainstay of the business, although commercial vehicle bodywork remained as a sideline. Unlike many, Harrington adapted well when standardisation of body designs by private car manufacturers in the twenties caused the decline of that part of activities. What work there was tended to be for bespoke chassis such as Bentley or Bugatti and this perhaps led to the upmarket image that Harrington continued to foster throughout their existence. In fact, cars continued to be a feature of Harrington work right up to the end of the company, but they were very much the minority. Production of luxury coach and bus bodies became the major occupation of the firm, with commercial vehicle bodies a smaller but significant proportion of the output. In 1930 a purpose-built factory known as Sackville Works was constructed at Old Shoreham Road, Hove. Not as bold as some new factories of the time the cement rendered facade could be described as falling somewhere between art nouveau and art deco. Displayed in large but elegant letters on one side was "Motor Coach Builders" and on the other side, "Automobile Engineers". The front was the narrowest part, and the production area, of conventional construction, spread out behind, on the triangular site. The factory occupied an area of seven acres and by the late forties over six hundred employees staffed the works. The factory may have seemed grand at the time but from the start there was no room for expansion. A railway bound it to the rear and East, a major road to the front and there was a graveyard on the West flank. The site area always limited production to approximately 200 vehicles a year and would be one, although not the main reason that Harringtons ceased trading. As an aside, rather than the factory expanding, widening of the road gate into Harrington's frontage and the spot where many vehicles were photographed later became a very risky place to stand. During the Second World War, work other than war effort stopped completely. The very few passenger vehicles that emerged from the works may be presumed to be either repair of damaged vehicles or for supply to the armed forces. Harrington certainly constructed a number of special vehicles for the Army, Navy and RAF. Part of the works was converted to manufacture air frame components. It is believed that this was primarily for the Westland Lysander aircraft, famed for its ability to land and take off in a small area and much used in contacts with the French Resistance. Another activity where Harringtons were proud to contribute was the production of prototype aircraft components and this eventually became a major part of war work. The techniques such as light alloy construction and jig manufacture were incorporated into post-war coach production, thus ensuring quick and accurate assembly. Prototype work such as this continued even after the war and through the fifties. During the 1950s, a greater use of glass fibre was successfully applied to their products, thus saving on the costly panel beating process. The early process with its use of an oxidising catalyst was particularly risky with regard to fire, or even minor explosion so the glass fibre components were constructed in a separate building behind the main works. Sometimes when curved repair panels for older coaches were required a fibreglass alternative was supplied to replace the original aluminium one. By the early sixties, when the success of the Cavalier coach was resulting in batches of large orders, the limitations imposed by the factory size were becoming more and more apparent and Harrington once again turned to the car side of their business in an attempt to maximise production area. Fortunately, eschewing the complete fibreglass replacement body so popular in the fifties they started modifying production sports cars and making fibreglass "GT" conversions (the "fastback" top was part of the bodywork and was not intended to be removable). Base vehicles were the Sunbeam Alpine, and Triumph TR4. Although hardly a GT, fibreglass was also extensively used in the PSV conversions to the Commer 1500 twelve-seater minibus. These were particularly successful. For the purchaser the attraction of this was that although the conversion cost more than the standard minibus full PSV specification vehicles were exempt from purchase tax and this helped make the project viable. Commercial vehicle bodies were also produced but these tended to be very specialist in nature with most bulk orders being Government contracts of some type. This had taken the form of specialised vehicles, such as a batch of Green Goddesses, Black Marias and RAF crew buses. Harrington had always been a family firm. Ernest G. Harrington and Thomas R. Harrington (the sons of the founder, Thomas) were Joint Managing Director and Chairman until 1960 and were very old indeed. (Thomas R. was 80 when he died in 1963). Arguably, in terms of business development things had been left to stagnate, but the small factory had always provided a good living. The company had made the decision to continue within the limits set by its production facilities at Sackville works. There were other members of the family on the board; Clifford Harrington had been a joint director since the fifties in charge of coach building. It was Clifford who was keen to embrace the best continental influences and was the prime mover behind the styling of the Cavalier and Grenadier. However, it was clear that things had to change. The bespoke work that had "filled in space" around the coach production was beginning to dry up. Harrington had been a Rootes agent since the thirties, the car dealership being run separately from the coach building side (there were showrooms in Hove and Worthing). The result of this special relationship was an intense interest when Harrington approached Rootes to see if there was anything they could do for them on the strength of their initial efforts with the Alpine conversion. It happened that Rootes were being lured into the exotic and expensive world of competition motoring and were looking for a closed body for an Alpine at Le Mans (presumably realising the Harrington output would enable it to be deemed a production model). Unfortunately, dark clouds were beginning to gather over the Rootes Group which would have dire consequences for many companies associated with them. Contrary to an often-reported story, Harrington never became part of the Rootes Group. Early in 1961 the Rootes family gained a financial stake when the Robins and Day group purchased Harrington. Robins and Day were owned by the Rootes family, but privately and outside the Rootes Group. As far as the Harrington family was concerned this should have provided a steady stream of specialist work from Rootes companies and potential for cash injection. Sadly, this was to be far from the case. Later there were some changes in management. George Hartwell came in to take charge of the Harrington Le Mans project. In November 1962, Desmond Rootes came on to the board as Director of Motor Trading. Clifford Harrington resigned from the board and left the firm. Gordon H. Harrington took his place as General Manager, Manufacturing (including coach building). At the same time Geoffrey Harrington was appointed to the Board as Sales Manager, Manufacturing division. The time of the Harrington Alpine was about over by then (an expensive diversion for Rootes which together with the Le Mans programme fell victim to the 1960's recession). The coupe was deleted from the Alpine range in 1963. The conversions on the Commer minibus kept the Rootes connection ticking over until near the end and in fact after the closure of Sackville works the fibre-glass conversions continued to be produced at Rootes in Maidstone although no longer badged as Harringtons. The firm was in a deadlock situation. As far as coaches were concerned no money was made available to develop new models, even though preliminary plans had been made for a replacement for the Cavalier / Grenadier range. The Crusader IV had seen a return to composite construction in order to reduce costs. It was also quite clear that the bespoke method of production that had served Harrington so well on its small site could no longer be made cost effective. This situation draws comparisons to the asset stripping that claimed many well-respected names in the motor industry during the 50's and 60's - especially since Robins & Day kept the Harrington car dealership sites running until the 1980s. Geoffrey Harrington had resigned in April 1965. Late in 1965 it was announced that the coach-building activities would be discontinued in the following year. The last coach was body number 3218, a Grenadier registered FFJ 13D delivered to Greenslades Tours of Exeter. It took part in the 1966 Brighton Coach Rally. It no longer exists, and it is believed that there was no particular feature on it that might have marked it as the last Harrington. Unfortunately, on the closure of the works most of the archive material relating to bodies built and photographs and drawings were destroyed. Later it is reputed that Harrington's official photographer lost much of his saved material in a house burglary. It is unlikely that it will ever be possible to compile a complete record of all the vehicles that left Sackville Works. The factory passed to British Telecom as a motor fleet service centre and was finally demolished in 1999. Plaxton took over the supply of repair panels for Harrington bodies and most of the fibreglass moulds went to Scarborough and in the fullness of time were scrapped. The Harrington name continued in motor sales, following the Rootes empire to Renault, and then as BMW agents until the 1980s. © 2005 N.L.E.Webster Taken from a 1955 edition of Commercial Motor. An advert for the Harrington Contender, featuring the Commer TS3 engine, the maddest diesel engine this side of a Deltic. A few more oldies: This particular gathering was held on a glorious day at Wythall and below are the pics of the magnificent vehicles that had journeyed from all areas to take part. Taken from a 1955 edition of Commercial Motor an advert for the Harrington Contender, featuring the Commer TS3 engine, the maddest diesel engine this side of a Deltic. Leyland Cheetah LZ5/Harrington C31F EYA 923, art-deco personified in a coach with its distinctive dorsal fin. EYA 923 was registered in March 1939 in the fleet of Porlock Weir, Porlock & Minehead Motor Services Co. Ltd., whose fleet name was Blue Motors. The chassis is a Leyland Cheetah LZ5 with a petrol engine, and the body work is by Thomas Harrington of Hove. It has an observation coach body with sunshine roof incorporating their famous dorsal fin. It seats 31 passengers. With the season just starting in early 1939 the coach operated on excursion and tours such as “over Dunkery”, “Lynmouth and Doone Valley”’ “Tarr Steps”, “Quantock Hills” and many other day, and half day/evening tours that Blue Motors operated. Later in 1939 when war was declared Blue Motors’ buses were requisitioned so EYA and other coaches began work on the bus service with coach excursions re-commencing immediately after the end of hostilities. EYA continued in service with Blue Motors until 1953 when it was sold to Sherrins of Carhampton (about 4 miles from Minehead). It was Leonard Sherrins first vehicle and Mr Eric Tarr one of Blue Motors’ drivers spent a week teaching him to drive to PSV standards. The next owner was a lady in Swiss Cottage, London who purchased the coach in 1959. She used it to go on holiday in the West Country and eventually purchased a property in St Tudy in Cornwall. EYA was parked on blocks as a sort of summer house in her garden. In 1989 it was given to the West of England Transport Collection at Winkleigh, Devon followed by purchase by its present owner in 1991. A total overhaul of the chassis and bodywork has been completed. A set of correct Harrington seats were fitted and all interior trimmings are now exactly as they would have been when the vehicle first appeared in 1939, including a set of matching knee rugs. A truly remarkable and stunning survivor, this 84 year old vehicle was driven to Wythall and back from Sussex without missing a beat. A magnificent line up Leyland Leopard L2 with 32-seat Harrington Cavalier body new in June 1961 These coaches were introduced in 1961 to replace the 1953 Royal Tigers on extended tours. They had high quality interiors with 32 reclining seats whereas the later batch for express services had 41 seats. They also had air suspension which was unusual at the time and not repeated in any subsequent Ribble Leopard coaches. The tour coaches were only used in the summer months being delicensed in the winter. Most like 1036 were based at Aintree depot. 1036 was first registered on 29 May 1961 and withdrawn after the 1971 season. It went to Norths (dealer), Sherburn-in-Elmet in Feb 1972 soon passing to Regent Coaches of Redditch in May. They withdrew it in Feb 1974 and it was acquired in May 1974 by Jacksons Coaches of Chorley who used it until 1986 mainly on the Works Service from Chorley to British Nuclear Fuels plant at Salwick. In October 1987 it passed to Maypole Coaches who planned to restore it. However, things did not progress, and it was sold to a Ribble Vehicle Preservation Trust member in 1988. For the next 10 years the vehicle owner almost single handedly overhauled all the chassis, axles, suspension, fitted new cross members and renewed much of the bodywork. The vehicle then went to Preston Bus for repaint into Ribble ivory and red livery. The vehicle then came to the RVPT depot where work was finished on the interior. This was completed in 2009 and 1036 has been a front-line vehicle since then. ABO 145B was one of a batch of six AEC/Harrington coaches delivered to Western Welsh in 1964 for extended tour work. Originally ABO had the AEC AH470 engine and AEC 5-speed synchromesh gearbox. She was delivered in the livery carried today with the stylish Harrington Grenadier coach body at a length of 31ft 10in and only 36 luxury seats. After approximately three seasons (the coaches being mothballed each winter), the livery for all Western Welsh coaches was changed to Peacock Blue and Ivory. As four new tour coaches arrived in the late 60s ABO 145B and a number of its sister vehicles went on to work for Greenslades Tours where she stayed for a number of years. ABO is known to have spent at least one full summer season on the Isle of Wight on Greenslades Island Tour work. After leaving Greenslades she passed through a number of independent operators before finding her way to Hall’s Coaches of Biddulph Moor, near Leek, Staffordshire who at that time operated a number of other Harrington bodied AEC coaches. In this 1980s pic it is seen passing through Goldenhill, Stoke on Trent working a mill contract on hire to fellow local operator Turner's. It is believed that whilst with Hall’s the original engine and gearbox were replaced with an AH505 engine and the AEC 6-sped constant mesh gearbox both of which are retained today. It was also whilst with Hall’s, and it is said that Mr Hall was driving, that ABO came together with the stone wall of the village church severely damaging the coach front. The ever-resourceful Mr Hall grafted on the front of a similar Grenadier coach (CIUW 560C new to Timpson’s) to return ABO to the road again. She is an example of the touring coaches seen up and down the country in the 1960s and 1970s, and to some eyes does not look too much out of place today. Entering preservation during 1987 she received the benefit of retrimming of the seats with a period moquette followed by a full repaint in 1989 – its next repaint was completed in September 2014. ABO is now currently based in the north-west having previously been garaged at the same location in Kent for 32 years. 1959 Seddon Diesel Mk19/Wayfarer IV VHO 200 new to Liss and District, one of just 30 examples of the Mk19 chassis. This Seddon chassis was built in 1958 to right hand drive and exhibited at the Commercial Motor Show, London in 1958. The 30 following production vehicles were all left-hand drive and exported. The remaining right hand drive exhibition chassis was purchased by Creamline Coaches of Borden Hampshire who had the Harrington body fitted (seen here) in 1959. This is the ONLY right-hand drive Seddon of this model in the world and she is still working for a living. Purchased by Thornes Independent in 1961 when only 2 years old she has remained with Thornes since. The vehicle is Tachograph fitted and will happily cruise at 55mph. At the 1959 Brighton Coach Rally It is 1963 and Lucy Thornes has prepared Seddon Harrington VHO 200 and Commer Plaxton (HHE 446) for a private hire 1958 AEC Reliance/Wayfarer IV 390 DKK, a Maidstone and District example. When first built this had been exhibited on the Harrington stand at the 1958 Commercial Motor Show. 1961 Bedford SB3/Crusader II 326 CAA new to King Alfred. This was the middle one of a trio of 1961 Harrington Crusader bodied Bedford SB coaches, which were sold off in 1969 and 1970 to Porter of Dummer, thus all three stayed together. At Amberley Chalk Pits alongside sister to 390 LKK above An AEC Reliance 2U3RA with Harrington Grenadier coachwork, new in 1965 as Surrey Motors, Sutton no. 52. It later joined the fleet of Classic Coaches, High Wycombe. With Surrey Motors inside the Maidstone & District Bus Garage, Hastings, East Sussex. Saturday afternoon 24th July 1971. Picking up in Bedford bus station A Leyland PS1/Harrington C33F dorsal fin. JYC 855 is from 1947, and was also a Porlock Weir coach from new and stayed with the company until its amalgamation with Scarlet Pimpernel of Minehead in 1954. It retains their red livery today. Withdrawn in 1960 it passed through a number of operators until John Brenson of Brentwood Coaches undertook a full rebuild. Seen abandoned in a yard From the early years of Harrington coaches, this Leyland Cub LZ2/Harrington C31F CUF 404 exhibited 1936 styling with a normal control/bonnet forward body. New to Southdown Motor Services and originally fitted with a roll-back canvas roof. Post war it revisited Harrington’s and was rebuilt with glass cant windows, with only the roof centre remaining in canvas. Following years of neglect it was rebuilt, a remarkable vehicle to see today. The early Leyland Cub was built between 1931-39, at their factory in Ham, South West London with the name later revived by Leyland for a 1979-87 model. A 1957 Harrington bodied Dennis Lancet UF that was new to Hutchings & Cornelius (H&C) of South Petherton, Somerset. It was withdrawn in 1974 and sold to Tor Coaches of Street who only used it for a couple of months before selling it on to The Brutonian Bus Co. of Bruton, Somerset. It was operated until 1976 when it was withdrawn and left unused in the yard. It was purchased for preservation in 1980 and for the next 24 years was comparatively unchanged standing in a yard near Slough. It passed to a new owner in 2004 and although some panels were removed by way of determining the overall condition of the bus, actual restoration work did not get underway until 2009. YYB 118 is one of only two Lancet UF known to survive from a production of just 62 chassis and is the only one that is anywhere near roadworthy. A set of pics showing the various stages of restoration: Dennis Lancet UF engine before and after Fuel tank before and after Rear end interior Progressing well Refurbished interior The finished vehicle looks magnificent 1963 Leyland Leopard L2/Grenadier C28F 750 DCD is in fact a ‘Grenalier’. Southdown liked the Cavalier front that permitted the use of an illuminated ‘Southdown’ name panel. Subsequent Grenadiers had similar fronts fitted. This ‘front end swapping’ was not a rare occurrence with these coaches. This dorsal fin is a very recognisable coach that has been immortalised in a 1:50th scale model, 1950 full-fronted AEC Regal III/Harrington FC33F KDD 38. Two of these coaches entered service with Soudley Valley in 1950 (one a Leyland Comet). This AEC spent its entire working life working in the Forest of Dean until laid up in 1973. Bought by its current owner, Nick Helliker, it was restored to its current condition, another remarkable survivor. The final dorsal fin is 1951 Leyland Tiger PS2/3/Harrington C35F HVJ 583. This coach was purchased new by Wye Valley Motors with whom it remained until 1972 when it passed into preservation. Harrington had a relationship with the Rootes Group, and Triumph illustrated by the legendary Harrington Sunbeam: 1962 Sunbeam Harrington C-Type with the complete set of Harrington optional extras of the time and owned by the same person for nearly 40 years. Having created a hatchback rear end for the Le Mans, Harrington redeveloped its Alpine to accommodate the much better boot-opening solution of the new design, while maintaining the ease of production of its initial model. The result was the Series C Harrington Alpine. “This is the earliest-known example of the Series C,” says owner Derek Hewitson. “The lady who first bought it was clearly quite forceful. She went to the 1962 Earls Court Motor Show and demanded to buy the very car featured on the stand. “The Harrington team wouldn’t sell it to her but made her one exactly the same. So it isn’t the motor show car, but it is an exact copy of it.” Derek has owned the Alpine for more than 40 years, having bought it in 1984 when struggling to find a decent Volvo P1800: “I had no idea what it was – I just liked it.” “After I’d had it a while I did some research and discovered how rare it was,” he explains. Derek had the Series C restored in 1987. The job wasn’t cheap but has stood him in good stead, and the car remains in much the same condition today. Looking after it has proved relatively simple because it is mechanically almost identical to an Alpine, but there are still challenges. “I’ve been looking for an overdrive switch for 30 years,” laughs Derek. “It was also fitted with a Clayton Dewandre brake servo unit by Harrington as an optional extra. “I’ve not been able to find new seals for it, so I’ve had to use a Girling servo instead.” A superb case of Harrington models Some non-Harrington vehicles now: The rear end of 472 Birmingham Corporation BON472C Daimler Fleetline CRG6LXSD Marshall new in 1965. Although it might look like a double decker that has lost its top deck, BON 472C was one of 24 purpose-built single deck Fleetlines that entered service with Birmingham City Transport between March and September 1965. After undertaking trials with Atlanteans and Fleetlines in 1961/62, Birmingham plumped for the Coventry built Fleetline, standardising on the type for its double deck requirements and large batches with Metro-Cammell and Park Royal bodies would arrive over the next few years. Meanwhile, a batch of 1949-built half cab Leyland Tiger single deckers were in need of replacement and a search was made for a suitable single decker. There was a desire to have a bus with level gangway and as few entrance steps as possible, meaning that underfloor engine types with their high floors and multiple steps would be unsuitable and that a rear engine chassis would be needed. However, the newly introduced types, such as the Daimler Roadliner, Bristol RE and AEC Swift, were too long for many of the maintenance pits at the garages where the buses were to be allocated, so the final choice came down to the Daimler Fleetline and the first order for single deck Fleetline buses (there had been a pair of Yeates bodied single deckers built for Shell-Mex BP as mobile racing car tenders in 1963). The bodywork order was placed with Marshall of Cambridge, a new name for Birmingham, but they produced a neat 37-seat design that incorporated the standard Fleetline engine cover and features that gave a family resemblance to the double deckers in use, although the side windows were set somewhat higher than usual and the BET curved windscreens were unusual for Birmingham. However, these would have been familiar to Marshall on the many BET single deckers they built. As the interior ceiling height was greater than their double deck cousins, these Fleetlines were able to have high mounted forward facing seats over the rear wheelarches. the 24 single deckers were delivered between March and September 1965 and were used on special services for disabled children as well as other routes. All passed to the West Midlands PTE upon its formation in 1969 and some went on to spend time in unfamiliar places away from Birmingham. A handful were reallocated to Walsall and others were loaned to Wolverhampton and former Midland Red garages to cover shortages. In later years they found useful employment on the Centrebus service around Birmingham city centre, but all 24 had been taken out of service by the end of 1981. Happily, two of them, 3472 and 3474, are now preserved. The picture shows 3457 in Dudley Bus Station in late 1974 probably on loan to the former Midland Red Oldbury Garage. Alongside 3457 is former Midland Red 6290 (YHA 290J), an Alexander J-Type bodied Daimler Fleetline that was new in January 1971 and spent most of its life at Dudley. Midland Red began taking Alexander bodied Fleetlines from 1963, building up a fleet of over 300, and 6290 was from the last batch which were equipped for one person operation with dual doorways. It was one of 50 Fleetlines that passed to WMPTE on 3rd December 1973 when the PTE acquired Midland Red’s operations based in what was to become West Midlands County the following April. 6290 was finally withdrawn in October 1982. (Photographer Roy Marshall, copyright The Bus Archive, ref RMMSB-16) A 1967 Bristol RELL6L - Cheltenham District Underfloor engined single-deckers, with their high floors and difficult entrances, became unpopular by the mid-1960s. Operators called for rear-engined single-deckers. Manufacturers rushed out poorly developed models which were mostly disasters. One reliable exception was the Bristol RE with variants covering two chassis frame heights for bus or coach work, two engines (Gardner or Leyland) and three lengths. This bus is to the most popular length of 36 feet (11 metres). The RE remained available to home market customers until the mid-1970s, by which time Bristol was owned by British Leyland which insisted on its replacement by the Leyland National. The first four bus bodied Bristol REs delivered to the Bristol Omnibus Co. were allocated to its Cheltenham District subsidiary. No 1000 was first licensed in June 1967 and, like Bristol's other early REs, was rebuilt in 1969 to front entrance and centre exit, popular at the time for urban driver only buses. It remained in Cheltenham until withdrawal in 1981, by which time it carried standard National Bus Company green livery. No 1000 came directly to Wythall and was rebuilt to original single door form and returned to Cheltenham livery. Western National (Royal Blue) 1411 Bedford OB Duple C29F 1950. This bus appeared in the 'Agatha Christie's Marple' episode called 'The Moving Finger'. 1947 Leyland Titan PD2/3 - Southport Corporation This bus is an entirely Leyland product. It was one of 12 delivered in 1947 to Southport Corporation and is a very early example of the legendary PD2 model, indeed the batch was the first to 8 feet width. It carries Leyland's own coachwork, originally with orthodox covered top. Being a coastal operator, Southport maintained a small fleet of open-top buses. By 1962-3 these Leylands were getting on in years but quite capable of easier work. Six were therefore converted to open-top for town tours but, unlike most such conversions, they became convertible rather than permanent open-toppers. The roof and upper deck windows could be refitted so that the buses could be used in the winter. It was claimed the conversion from open to closed top could be achieved within half an hour. This bus was sold in March 1974 to Banham International Motor Museum, Diss and resold in April 1983 to the London Toy & Model Museum, Craven Hill, London where the upper deck was used for children's parties. It was donated to Wythall in November 1992 but set an interesting extraction job as a building had been erected in front of it! Body restoration has steadily continued since it arrived. Principal mechanical attention has included a replacement engine and full overhaul of the cooling system following major frost damage with a previous owner. 1953 Guy Arab IV - Metro-Cammell DD (27 ft) This was the final development of Birmingham City Transport's classic design of front engined bus. There were around 600 buses built between 1951 and 1954 with this style of body which was one foot longer and featured deeper windows. Internally the straight staircase, polished wood and stainless steel brightwork remained but there was less moquette in favour of cheaper leather cloth. They were the first standard Birmingham buses not to have the upper and lower decks built separately. They were based on Daimler and Guy chassis with easy change preselective gearboxes and bodies by Metro-Cammell or Crossley. Most Guys at home and abroad had crash gearboxes but, after the Second World War, an easy change gearbox was an option although a rarity outside the West Midlands. Initially this took the form of a Pre-select design, attracting the attention of Birmingham City Transport which standardised on such gearboxes. Birmingham purchased 301 Guys of which only six had crash gearboxes. 2976 is a typical Birmingham Guy with Pre-select gearbox and entered service in February 1953 from Acocks Green garage. It moved to Miller Street in October 1967, to Harborne in May 1969, and to Washwood Heath in August 1971. It had been absorbed into the West Midlands Passenger Transport Executive in October 1969 and received the new fleet names but still carried its old colours when retired in January 1972. It was purchased for preservation in June 1972 and sold to the Museum in January 1983. Both the original preservation owner and the Museum have carried out a considerable amount of work, including removal of an offside illuminated advertisement panel fitted in the early 60s. The effort was rewarded by successful passing of the appropriate test, allowing 2976 to join the Museum's fleet of full pcv licensed buses in the 2000 season. A 1934 Midland Red Single Decker SOS CON - SOS 8.028 litre with a Short Bros body HA9483 was new in September 1934 as a SOS ON ('ONward') with a BMMO 6.37litre petrol engine and Short Bros 38-seat body. Later, it was fitted with a BMMO diesel engine, returning to service in February 1938 as a type CON ('Converted ONward'). Diesel engines were more economic than petrol, having about one-third the fuel consumption per mile, and a lower rate of tax on the fuel oil. It was based at the following Midland Red garages: Leamington and Hinckley (1935-42), Worcester (1943), Leamington (1944), Leicester Sandacre Street (1944-45), Rugby (1946-1952), Birmingham Sheepcote Street (1952-53), and Redditch (1953-56). Fleet number 1532 was applied in March 1944. Its body was rebuilt by Nudd Bros & Lockyer, returning to service in November 1949. Withdrawn from service in November 1956, it was sold four weeks later. HA9483 was the last of three SOS single-deckers bought by Birmingham Corporation Water Department as staff transport for its works in the Elan Valley. One was later converted into a lorry for carrying pipes. However, HA9483 had a luckier fate by being acquired by the Digbeth S12 Group for preservation in April 1968. Preservation While little or no work was done, HA9483 was fortunately placed into secure undercover storage where it remained for half a century, largely complete, gathering a multitude of cobwebs! HA9483 was donated to the Museum in November 2022 but initially remained in its existing accommodation. It arrived at Wythall in March 2023 after several weeks of preparation to extract it from the corner of the building and manoeuvre it along a narrow track onto a low-loader. AEC Matador 7.7 litre towing Lorry Midland Red bought this World War Two AEC Matador from the War Department in 1947 for use as a recovery vehicle. The company gave it a new body in 1962 using bus and coach parts. The distinctive windscreen was identical to Midland Red's original motorway coaches, nationally famous at the time. The rebuilt Matador soon became a celebrity vehicle among bus people in the area. The Matador was based at Birmingham Digbeth garage for many years and, after the old company was split, passed to Midland Red West. It was eventually sold to North Birmingham Busways as their recovery vehicle. A 1940 SOS SON – 8 litre – Brush SD Midland Red, which served nearly every town and village across the Midlands, had to give up building its own buses and coaches during World War Two. This bus is from the last series of 50 single-deckers in production as war broke out in 1939. Fuel could barely be spared for private cars during the war but there was a huge growth in demand to factories on war work so public transport took the strain. In 1939 Midland Red carried 210 million passengers but this increased to 327 million by 1944, despite the shortage of new buses and loss of staff to the forces. Buses were subjected to continuous heavy overloading, and shortages of maintenance staff and materials. Make-do-and-mend ideas kept them on the road. Heavy renovation was required when peace returned, the body of this bus being rebuilt by Nudd in 1950. GHA 337 finished passenger service in 1958 and found a new career with a showman. GHA 337 was discovered in a scrapyard at Worksop; the body was rotten but it retained most of the key mechanical parts and was bought for preservation in 1978. The bus was stored for many years as it needed total restoration, this being completed in 2012. It has been restored to 1950 condition. CBD 778K No 778 Ex United Counties Bristol VR, new in December 1971 as a series 2 VR but later converted in 1984 to Series 3 spec with a new round front. 1951 Daimler CVD6 Metro-Cammell DD Many enthusiasts refer to the Birmingham Standard Bus but, in truth, they were far from standardised and subject to constant evolution. Operators had to accept different types of bus in the years of shortage after World War Two. Birmingham renewed its fleet with around 1750 buses and the most numerous type, with 438 received, was the Daimler CVD6 with Daimler's own engine - renowned for being smooth but thirsty for fuel and water in comparison to the Gardner engines often fitted. This bus belongs to a contract for 150 buses that introduced the second generation of Birmingham's 'New Look' body with concealed radiators. The upper and lower decks were now built together instead of separately. Deeper windows were introduced, and the interiors were reduced in quality - bus operators were coming under financial pressure, not least due to increases in fuel tax. This bus, number 2707, spent most of its working life from Liverpool Street garage and passed with the rest of the fleet to the West Midlands Passenger Transport Executive in 1969. Alongside is a 2002 Dennis Trident 2 Alexander ALX400 2000s West Midlands Low Floor Double Decker From January 2001, the Public Service Vehicle Accessibility Regulations required that all new buses on scheduled services should have easy-access low floors, with specific provisions for the carriage of wheelchairs and priority seats for passengers with limited mobility among other features. Travel West Midlands ordered a total of 360 Dennis Trident 2 chassis fitted with Alexander bodywork to satisfy its need for PSVAR-compliant double deckers. They were delivered in several batches, during which time the manufacturers' names changed from Dennis and Alexander (separately) to Transbus to Alexander Dennis: 4125 to 4224 (April to August 2001), 4305 to 4404 (February to December 2002), 4405 to 4414, always based in Coventry (January 2003), 4425 to 4474 (June to August 2003), 4535 to 4584 (January to March 2004), 4585 to 4634 (July 2004 to January 2005). While Travel West Midlands would have specified its choice of seats, destination equipment, interior colours, etc., this was a combination of chassis and body to be found in many fleets around the country. In the next bay the back end of a mid-1960s Midland Red single-deck bus is visible: A 1966 BMMO S17 fitted with a BMMO 10.5 litre engine and Plaxton SD body Midland Red's first single-deck design built from 1962 to the newly permitted length of 36 feet (11 metres) was the BMMO S16. This was a stretched version of earlier buses, retaining the 8 litre engine and manual gearbox. The extra weight and length meant S16 drivers were hard pressed to cope. The S17 was introduced in response in 1963 and, although looking very similar, the mechanical components were significantly updated by employing the 10.5 litre engine and semi-auto gearbox first seen on the D9 double-decker. The result was a competent and reliable service bus which remained in production until 1966, by which time over 260 had been built. With a modest unladen weight of around 6.5 tons, the S17s were lively and rugged with plentiful reserves of power, well suited to all areas of the company's operations. To speed construction Midland Red sent most S17 bodies to Plaxton or Willowbrook for completion. 5767 entered service from Leicester (Sandacre Street) in September 1966. It was moved to Wigston garage in October 1967 and survived to become one of the last half dozen S17s in service, retiring in September 1979. A 1966 Daimler Fleetline CRG6 - Gardner 6LX - Alexander DD While BMMO was manufacturing its own D9 double-deckers at Carlyle Works, it supplemented its double-deck fleet by purchasing Daimler Fleetline chassis from 1963 onwards. These were fitted with Alexander bodywork, based on a style introduced for Glasgow Corporation, but with two-piece flat windscreens on both decks instead of Alexander's usual curved screens. (BMMO no doubt had a view on cheaper spares!) There were 50 in 1963, designated DD11 type, 149 from 1966 to 1968, designated DD12 type, and 103 from 1969 to 1970 designated DD13 type. There were detail differences between the types, most notably that the DD13 type had a centre exit. GHA 415D (fleet number 6015) is one of the DD12 type and was new in November 1966. It served at Leamington, Kidderminster, Worcester (twice), Evesham (twice) and Tamworth before a few months in store at the end of 1979. It then resumed service at Coalville in 1980 and became part of Midland Red East when the company was split in 1981. Finally, it was withdrawn in December 1983. In 2026 the Harrington Gathering returns and is well worth coming to if you are free that day: Out and About 2 Extwistle Hall Extwistle Hall is a historic Grade II listed mansion which stands on a ridge of land between the valleys of the Don and Swinden Water in a bleak and commanding situation high on Extwistle Moor in Briercliffe, Burnley. The hall was built in the 16th Century in 1585 in the Tudor style by the Parker family, a prominent family at that time and although not medieval it does have medieval connections. Robert Parker had bought the land, which had previously belonged to Kirkstall Abbey, in 1537 after the Dissolution of the Monasteries. The Parker family occupied it for some 200 years before moving to Cuerden Hall around 1718. John Parker was High Sheriff of Lancashire for 1653, and Robert Parker for 1710. The house was remodelled in the late 18th century. Extwistle Hall was, first and foremost, designed as a place in which to live. The family who lived there might have regarded it as a Manor House, with Manorial functions, but its primary object, when built, was to provide a home. During the reign of Queen Elizabeth I the dubious sport of bullbaiting was at its height and a bullring was situated in the vicinity of the hall. The bullstone, a bulky piece of millstone grit is now built into a nearby wall. The Hall remained the home of the Parkers from the 16th Century to the early 18th Century. It was a curious but tragic accident that severed their association with Extwistle. On Thursday, March 17th, 1718, Captain Robert Parker went out shooting on a day that turned out to be wet and stormy. Consequently at the end of the day's sport he returned to the house thoroughly drenched with rain. He removed his greatcoat and laid it in front of the fire to dry. Unfortunately, he had omitted to remove his powder flask that still contained a large quantity of gunpowder and the result was that an explosion took place. Captain Parker, along with two of his daughters, Mary Townley and Betty Atkinson, and a child, were seriously injured, and there was considerable damage to the dining room in which the accident happened, with two other rooms also set on fire. Unfortunately, Captain Parker succumbed to his injuries and died a month later. A more unlikely tale records that the same Captain Parker, when returning from a Jacobite meeting late one evening, saw a goblin funeral procession pass through the gate at the top of Netherwood Fields. The ghostly cavalcade passed on in deep silence, a train of little men bearing the coffin, on top of which, as it passed, he saw his own name inscribed and this he saw as an omen of his own death if he did not renounce the Jacobite cause. According to the story he severed his Jacobite connections but alas he could not save his life. After this tragedy the family moved to another residence, Cuerden Hall, and the old house at Extwistle appears to have been abandoned to dilapidation, although part of it was occupied as a farmhouse. A former wing on the west side fell down some-time during the first half of the 19th century destroying what is said to have been one of the best apartments, and others known as the ladies' rooms. It is now owned by an Isle of Man based property company, has been unoccupied for more than 50 years, and is listed in English Heritage's Heritage at Risk Register. In early 2012, £2million plans were revealed to save and restore the hall to its former glory, then afterwards to be sold off. The pics: In the surrounding countryside some of the footpaths have been paved with reclaimed mill flagstones The River Don is crossed Followed by the very quiet Houghton’s Farm which appeared deserted The outbuildings, and adjacent Extwistle Hall come into view As it was: And now: The north side wall with moulded coping In front of the house is a small, flagged courtyard 43 ft. long by 33 ft. in width partly enclosed on the west side by the north-west wing, and on the east by the lower buildings. It is now heavily overgrown. The great hall, which is 24 ft. by 21 ft., occupies the eastern end of the first floor of the main block and is approached from the forecourt by a wide flight of stone steps. Again, all this is slowly becoming buried by nature. The stonework, door, and window frames are magnificent. The flight of stone steps The five-light mullioned window above the lower floor This one has small fragments of the original glass and lead remaining A solid archway in to the lower floor A more recent attempt at stabilising the structure has seen the use of Accrington bricks The Enfield Brick & Terra Cotta Co. Ltd was founded in 1893 by Stephen Holgate, quarrymaster, Charles Foster, builder, and others. By 1900 they employed 100 people and produced engineering, and rustic bricks and terra cotta specials. The works were sold to the Accrington Brick and Tile Co Ltd in 1938 when the Enfield company moved to new works at Deerplay. Production continued here until 1978. Internal wall structure The main hall Central joists Corner lintel Stairs to the second level Upstairs Ceiling on the second floor Entrance to the outhouse The south wall of the hall is occupied almost entirely by the fireplace, the Tudor arched opening of which, however, is now bricked up, and the room is in a more or less dilapidated state. A Towneley brick remains. The Towneley Colliery worked to 1948 and was situated along with the brickworks adjacent to the Todmorden to Accrington railway line, on the southern flank of Burnley by Towneley Park. The south side of the hall A high recess with a small window The east face The old gateway to green pastures In the distance an enclosed barn The adjoining stone cattle barn A later brick addition to a doorway An old entrance has been blocked up. Note the wooden lintel. A fascinating place that i very much doubt will ever be restored. Odds and Ends London Transport Posters The London Transport museum at Covent Garden recently held an exhibition of posters from the past: Too much of a good thing – 1910 Bluebells at Kew Gardens – 1920 The new Rose Garden at Regents Park – 1920 The Zoo Alphabet – 1928 Zoo – 1930 Between 6 and 12 – 1930 Power – 1931 - I thought this one stood out really well Aldershot Tattoo - 1934 More light - brighter travel – 1935 Your fare from this station – 1936 Chestnut Sunday at Bushy Park – 1936 See London’s parks and rivers – 1938 Memories of Plough Lane with this one: Torchlight Tattoo – 1939 Please stand on the right of the escalator - 1944 London Transport at London’s Service – 1947 Buy stamps in books – save time - 1955 Books of stamps save time – 1956 Tomorrow to Fresh Woods and Pastures New - 1956 London Transport conducted coach tours – 1960 Fly the Tube to Heathrow – 1987 The Pressed Steel Company of Great Britain Established in 1926 as a joint venture between William Morris, the Budd Corporation and an American bank. The new venture started up by supplying car bodies to Morris's Morris Motor Company, with its plant being located alongside. By the 1950s, the company was making bodies for most of the major car companies in the UK including Rolls-Royce, Rootes, and the Standard Motor Co. The company later diversified into rolling stock, and refrigerators under the brand name Prestcold. In 1966 The company merged with Jaguar and the British Motor Corporation (BMC) to form British Motor Holdings (BMH). When production started at Pressed Steel in 1926-27 the technology was new and untried, thus there was a steep learning curve before anywhere near perfection was reached. The first cars at Cowley using the all-steel technology saw the first Morris Oxfords with ripples in the panels, doors that did not properly close, and windscreen apertures that were so badly formed that rain water would have poured into the car. Poor quality steel was a major problem, and it took until the May of 1927 before the quality was satisfactory. Seen here is a Morris all-steel body that has been transferred to the moving production line and where the operatives are using a jack to adjust the body in order that the doors properly hang and close. A process which improved the quality and speed of the all-steel technology was electric welding. Pressed Steel erected its paint shop in 1926, but between 1937 and 1938, new paint and trim shops were built in preparation for the war effort. The painting process was still a manual operation as can be seen here, but note the absence of protective clothing, goggles and mask. Once the painting was finished the body was ready to be mounted on the waiting chassis. The post-war years gave way to a new generation of cars with then modern styling. In this instance the Morris ‘MO’ Oxford reveals its close relationship with the smaller Morris Minor, the MO being a scaled-up version in styling as well as engineering. The monococque bodyshell has arrived from elsewhere at Pressed Steel to be prepared for the ‘Rotodip’ rust-proofing process. The Rotodip facility was based in the E-Block at Cowley and was one of the most significant investment programmes at the works. The MO Oxford was a lethargic performer with its side-valve engine of 1,476cc developing a very modest 40.5hp to attain a top speed of 67mph via a glacial 0-60mph acceleration of 41.4 seconds. Photographed in 1961, this is the Jaguar line where soldering Mk X bodyshells was undertaken. It is interesting to note the level of clothing and goggles worn by the personnel. The car suffered from poor aerodynamics and was far too heavy. When Rolls-Royce developed its post-war models the firm’s traditional coachbuilders were without the capacity or facilities to produce coachwork in the volume that was required. Nevertheless, Rolls-Royce remained a strictly low-volume car maker, and an approach to Pressed Steel resulted in a contract to produce what were known as ‘standard steel’ bodies for the Bentley Mark VI, Rolls Royce Silver Dawn and, from 1955, the Silver Cloud and Bentley S. In 1975, Rolls-Royce introduced the Silver Shadow with its monocoque bodyshell. The expense of the car demanded it be produced in far greater numbers than previous models. Pressed Steel’s cost for the tooling was £1.4m. Once the unpainted bodyshells (known as ‘body in white’) were built at Cowley they were transported to Rolls-Royce at Pyms Lane, Crewe where they were checked for defects and measured for accuracy. Any imperfections were corrected at Crewe, and once addressed the bodyshells were adapted for right- or left-hand steering as appropriate, and then subjected to anti-corrosion processes, primer and final painting before being united with running gear and interiors. Routemasters on the 159 Run – 20th Anniversary Celebration! This year marks 20 years since the final Routemaster ran in public service on Route 159. For two decades that historic day in 2005 has been commemorated, and while it’s usually a relaxed get-together, this milestone year deserved something special. Last Saturday (Dec 13th) at the Ace Café near Wembley, North-West London, there was exclusive use of the car park from 08:00— perfect for displaying vehicles, meeting fellow enthusiasts, swapping stories, and soaking in the rare sight of so many Routemasters gathered in one place. While this was not a public running day, and the Routemaster Association was not organising free rides, many owners traditionally offer spare seats informally — so there was often a chance to hop aboard. The Ace Cafe was established in 1938 on the then brand new North Circular Road surrounding London. It was a simple roadside Cafe catering to travellers, particularly truckers. With its proximity to Britain’s fast arterial road network, and being open 24 hours, the Ace Cafe soon attracted motorcyclists too. In world war two, the building was badly damaged during an air raid on the adjacent railway marshalling yards. After the war the Ace Cafe was reopened in temporary accommodation and subsequently rebuilt in 1949. Changes in the social order, the growth of the car market at the expense of the motorbike industry, and the expansion of the motorway network saw the Ace Cafe serving its last egg and chips in 1969. The Ace Cafe Reunion is the brainchild of Mark Wilsmore. In 1993 he shared his ideas for an annual event to mark the closure of the original Ace Cafe, a book and film documenting the history of the Ace Cafe, and endeavouring to ensure that the original Ace Cafe re-opened, with relevant products being available. To mark the 25th anniversary of the cafe’s closure, Mark, with friends, formed the organising team for the Reunion and arranged for motorcycle runs to converge at the former Ace Cafe site on Sunday 4th September 1994. They got the planning permission, and ACE CAFE LONDON bought the original Ace Cafe site. As from December 7th 1997, a part of the original and legendary Ace Cafe site was re-opened on Fridays, Saturdays, Sundays, Bank Holidays and on the first Wednesday of every month. 2001 - and the Ace Cafe is alive and kicking. No – it´s not 1964, welcome back Ace Cafe! The 75th Anniversary in 2013 As it is today Plenty of events Some views inside The timetable for the day: The first to arrive was RM158 RM158 was one of 184 buses fitted with air pipes for suspension but this was never used on the central fleet of buses. Poplar, Walthamstow, West Ham, and Battersea were early allocations. The late 70s/early 80s saw spells at Upton Park and Willesden from where it was withdrawn in 1985. RM848 (on the left) was new in 1961 at Edmonton, later moving to Wood Green. In 1966 she was at Stamford Hill garage, and in 1967 received a new Leyland engine. She was sold in 1986 to Blackpool Transport, working there for 10 years. In 1997 the vehicle was acquired by Reading Mainline Buses, remaining there until 2000. In that millennium year she was bought back by Transport for London and refurbished at Marshalls of Cambridge. In 2001 the bus received a new Scania engine. By 2004 she was on route 9, then transferred to Arriva for route 38 out of Clapton. In 2005 she was re-registered to 448 UXS, and the following year went into private ownership. She was acquired for preservation in 2007, re-registered WLT 848 and is now in London United livery (no cream band). RM2217 was new at Willesden garage in 1965. In 1984 she became a showbus for London Transport, and was fitted with an Iveco engine in 1991. In 1994 she received a branded livery for route 159 out of Brixton. In 1995, when London buses were privatised, she went to Arriva, where she continued working. The vehicle was fitted with a Cummins engine in 2001, was refurbished at Enfield, and returned to Brixton garage. In 2004 she ran on the last day of route 137, and the last crew day of route 73. The same year she was given a Harry Potter livery and sent round the UK on a promotion tour. She has been recently repainted into the South London Esque LBC livery. RML2583 was built 44 years ago in 1966. RML stands for Routemaster Lengthened – it is 30ft long and seats 72. It was originally fitted with an AEC engine but this was replaced by a Cummins C in the RML refurbishment program of the early 90's. This is a slightly unusual Routemaster as it was used by London General to do trips outside London so was fitted with a high-speed diff which means it can quite happily cruise at 50/55 mph compared to the normal speed of 40mph. It began service in London on Route 14 operating from Putney Bus Garage in November 1966. In 1994 the process of privatisation of London bus services began, and the Routemasters were transferred from London Transport to twelve new operating units. RML2583 moved to New Cross Garage in October 1994 under London Central. In July 1995 it was branded for Route 36. In March 2002 it moved to Camberwell Garage for service on Route 12. In August 2002 it began service on Route 11 from Stockwell Garage until 31st October 2003 when it returned to Camberwell and Route 12. Its last day of service was on 5th November 2004 after 38 years on the streets of London and was bought by Ensignbus. In December 2004, Ensignbus held a raffle for thirty-two Routemasters available for £2,000 to those who could prove they had the finances to store and care for them. RML 2583 was bought by the Welsh Museum of Transport in Swansea. In June 2008 London Bus 4 Hire bought RML2583 for advertising and preservation. It was a tight squeeze parking her up Sorted RM5 was the first of the production Routemasters (the first four being prototypes). It began work at Willesden in 1959 on route 8, but was transferred to West Ham as part of the trolleybus replacement programme. She was also operational at Peckham, Sidcup and Palmers Green where she spent eight years on route 29. In 1984 she became a showbus but occasionally worked on passenger services. In 1994 she was transferred to the privatised Leaside Buses which became part of Arriva in 1998. In 2002 she was fitted with a new AEC engine and was seen on the final Routemaster days of various routes in 2004. She was restored to as near original condition as was practical by Arriva London in 2008. Raising the flag A lone RF in the form of NLE 600 arrives RF600 (NLE 600) is a London Transport Country Area Regal Mark IV and was built in June 1953 by AEC at Southall. After 18 years of service with LT at Hertford and St Albans garages, and four years in service with independent operators the bus was sold and has been preserved by a succession of enthusiasts. It was purchased by its current owners in September 2010. RF 600 is a regular at bus running events in London Country and Southdown territory. Alongside NLE 600 is RM2116 RM2116 was delivered to London Transport in December 1964. It operated in standard red livery until 1983 when it was one of several buses of different types to be given a special livery to mark London Transport's 50th anniversary (all buses received the anniversary logo seen to the front of the side of the bus). RM2116 by then a showbus for Seven Kings (AP) bus garage, was one of the batch of buses to receive a red/white/black/silver livery which resembled the 1933 version of London Transport's livery. It was also given the name "Forest Ranger" at this time (applied on the forward part of the white lower deck side window region). Unlike all the other anniversary buses, which were eventually repainted back into standard liveries, RM2116 was withdrawn from service in May 1984 and sold to the LT Sports Association, still in the commemorative livery. It has since passed through a number of owners. RM188 entered service at West Ham in February 1960. After allocations to six garages it was sold to East Yorkshire Motor Services in 1987. After withdrawal by East Yorkshire, it was saved for preservation in 2005. This beauty was my transport for the day. At Aldenham Works RM188 is seen undergoing a tilt test. (Credit to Richard Simons) In Hull in 1995 (Credit to Walsall 1955) The arrival of RCL2233 (Routemaster Coach Lengthened) A brief history: RCL2233 was one of 43 Routemaster coaches built for Green Line use and entered service in June 1965 from Romford on routes 721, 722, 726. Repainted into a simpler Green Line livery in May 1968 it worked route 704 & 705. In January 1970 transferred to London Country, and in 1972 downgraded to bus services. CUV233C was bought back by LT in December 1977 and the following month became a trainer vehicle out of West Ham still wearing her green livery. In December 1978, 2233 was repainted red although still on trainer duties. In 1980 RCL2233 was converted to a bus (doors removed, bell chord installed, re-seated, stanchion fitted) and entered service on the 149 from Stamford Hill until December 1982 when she was withdrawn from service. Brought for preservation by Alan Brown in February 1984 but due to a mix-up the vehicle was nearly scrapped by Norths in Sherburn. Alan restored CUV233C back to her early Green Line livery and rallied her for many years. New owners purchased her from Alan in July 2005 and have since carried out internal re-painting of the drivers cab, stairs & rear-platform area, complete refurbishment of the luggage racks, mechanical work including in late 2006 replacing the B-frame (rear subframe). In addition, all the tyres have been replaced, the registration plates changed to the correct font, the indicator ‘ears’ replaced and a complete new set of destination blinds purchased. Whilst the AEC AV590 (9.6ltr) bus engine fitted to 2233 was a good engine the RCL was under powered being much heavier (8 tons 3cwt) than a standard Routemaster (7 tons 7cwt). It was originally built with an AV690 (11.3ltr). It was decided to find an AEC AV690 engine that the RCL would have had when new. Eventually one was found and it was fitted in February 2010. Now 2233 cruises beautifully with little effort. In 2012 all the seats were refurbished and reupholstered with new foam cushions and the original-style grey Routemaster Coach moquette. In early 2013 the platform flooring was replaced with new ‘Treadmaster’ slats. During 2014 some repainting was done both internally and externally and the underneath silvered again, along with the refurbishment and repainting of the wheels. Many running components have been replaced or refurbished including the gearbox, accumulators, diff oil seal, brake cylinders and rear shock absorbers which are different to standard RM/RML as the RCL has air suspension on the rear. June 2015 was the 50th Anniversary of RCL2233 and the RCL class of vehicle. RM545 (WLT 545) is a unique, one-off AEC famously fitted with a DAF engine in 1988 for London Buses' experimental trials, making it distinct from standard Routemasters. It is a popular subject for enthusiasts, often appearing at rallies and in heritage collections, showcasing unusual engine swaps. It's a standard-length RM model, known for its distinctive engine and preserved condition. RML2440 (reg. JJD 440D) was delivered to London Transport in May 1966, in the dark green livery for use in the outlying 'Country Division' garages. In January 1970 it passed to the newly created London Country Bus Services when the country area was passed from London Transport to the National Bus Company, with the dark green livery retained but the cream band replaced by yellow, and with the application of yellow London Country fleetnames and logo. It lasted in service long enough to be one of the several London Country Routemasters bought back by London Transport, of RML, RMC and RCL class. After being bought in June 1979, it was stored and then overhauled, finally entering service in red Central Area livery in August 1980. As with all RML buses, in the early 1990s it was re-engined (Cummins) and refurbished. It saw use in London into the privatisation era, passing in 1994 into the fleet of London Central, who in July 1995 route-branded it for use on route 12. In April 2004 it was sold to dealer Ensignbus, and a year later sold into private hands for preservation. After restoration to its original London Transport Country Area livery, it has been an active participant in rallies and events ever since. The contrast in the colour green A quality line-up A photo shoot for the drivers With the offer of a donation to the fuel fund I was welcomed aboard RM188 with a choice of seats. It just had to be the front seat where the engine can be heard in all its glory. Before leaving driver Tim announced he was going to make her fly and boy was he right. No quarter was given to any car drivers dithering about, or changing lanes on roundabouts either. He just sent it up the inside! Our destination was the Bull at Streatham 15 miles away which would normally take around 50 mins. With the Christmas shoppers, and Lambeth Bridge closed it added around 30 mins on to the journey but that was a bonus travelling on such a classic vehicle. Bus lanes were only used when it could be seen that they were empty up ahead. A couple of times early in the journey we got delayed behind a service bus that was picking up so we tended to merge in with the traffic at this point. A convoy of four left the Ace and we headed down the A40 Western Avenue towards Paddington. Behind RML2744 on the A40 We soon got split up however owing to the many traffic lights. From there it was along Oxford Street, Marble Arch, Park Lane, Victoria Street and over Westminster Bridge which was absolutely heaving with people. The tourists were loving seeing a proper London bus with the Houses of Parliament as a backdrop. Plenty of pics were taken on their phones, some even standing in the road in front of it! Approaching Parliament Square with the Elizabeth Tower just coming into view on the right behind the tree, and the London Eye on the left. From there it was down to Brixton via Vauxhall for a photo stop of RM5 & RM2217 inside the old tram depot. This was a London County Council Tramways built structure which was opened on 6th March 1924. It was originally intended to house trailer cars that had been used by the LCC on busy routes in South London since 1913. However, before it could open trailer operation was discontinued in 1924 and it instead became a tram depot. There was a conduit change pit at the entrance with power inside the shed being taken from overhead wires. It closed on 7th April 1951. The subsequent history of the depot building is a bit more unusual as it was used for commercial purposes for a number of years following its closure as a tram depot, including a long period as a car showroom. It remained in the ownership of London Transport (and its successors) however so when Ken Livingstone expanded the bus services in the 1990s it became an outstation of Brixton Telford Avenue bus garage (itself a new building built on the site of an old tram depot). Today it is owned by Arriva London and is used for the training bus fleet and overflow from Telford Avenue. The tram tracks are clearly visible in the floor of the depot and appear to be in good order A short distance further along and we come to our destination of the Bull at Streatham. The Bull in Streatham is an historic Young's pub built in 1768 and formerly known as The Pied Bull. They have kept its heritage with the original bar and stained-glass windows. RM2217 joined us Followed soon after by RM158 & RML2583 After returning to the Ace around 16:00 we had a couple of hours before setting off for the Christmas Lights run. A fine end to a fabulous day👍 Next time: Auschwitz II Birkenau

- Yesterday

-

Dom148 changed their profile photo

- Last week

-

Theyve arrived! A3 - £15 plus postage 😍 Last day for shipping in time for Christmas is Monday - limited amount available! message or contact Jacklyn

-

1

-

Lap boards are out for christmas posting! https://www.ebay.co.uk/itm/177553603073?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=ytdrcybmsx6&sssrc=4429486&ssuid=4REhoG7FR7e&stype=1&var&widget_ver=artemis&media=FB_MSG&fbclid=IwY2xjawN7XKdleHRuA2FlbQIxMQBzcnRjBmFwcF9pZBAyMjIwMzkxNzg4MjAwODkyAAEeoThmUGY7W3FSyEcID2b5TaYZ8INun2XQjmhWnFze9w4X58_N5waWz61VZHs_aem_QUd3UQ2tKmyJXB7zTn7s4A

- Earlier

-

Twisty51 joined the community

-

ianbanny joined the community

-