-

Joined

-

Last visited

-

Days Won

185

Everything posted by Roy B

-

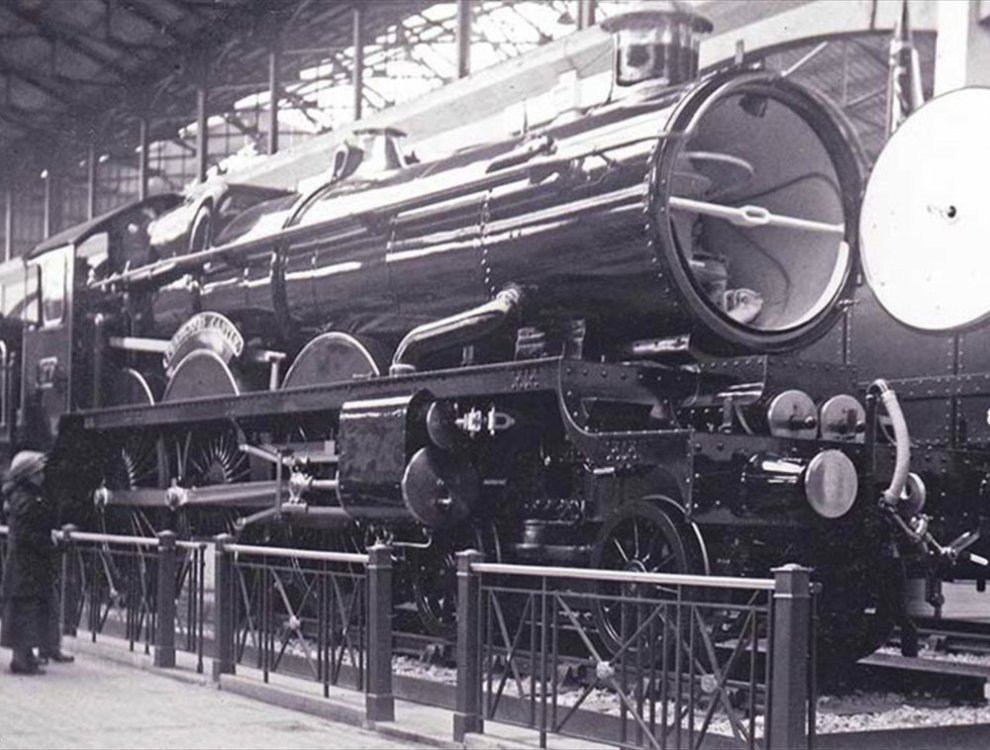

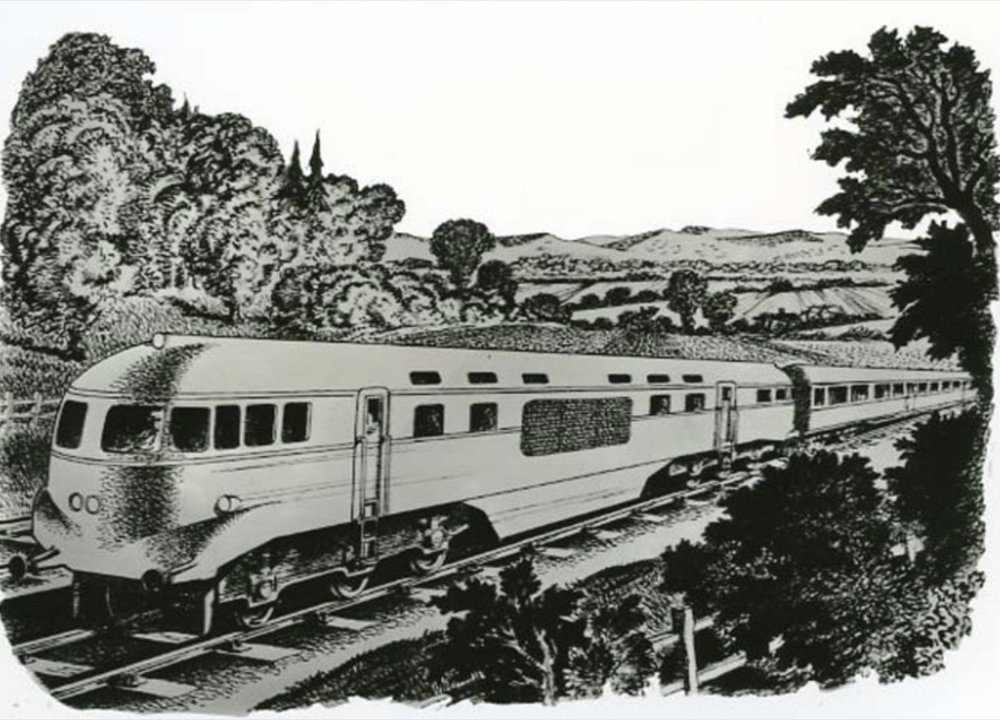

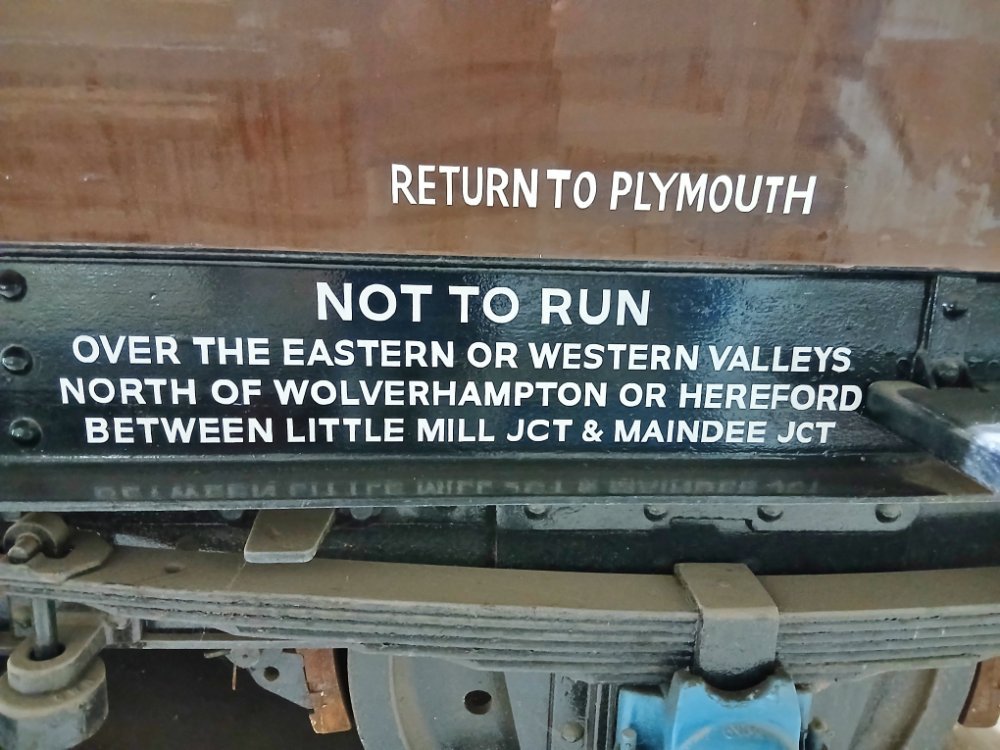

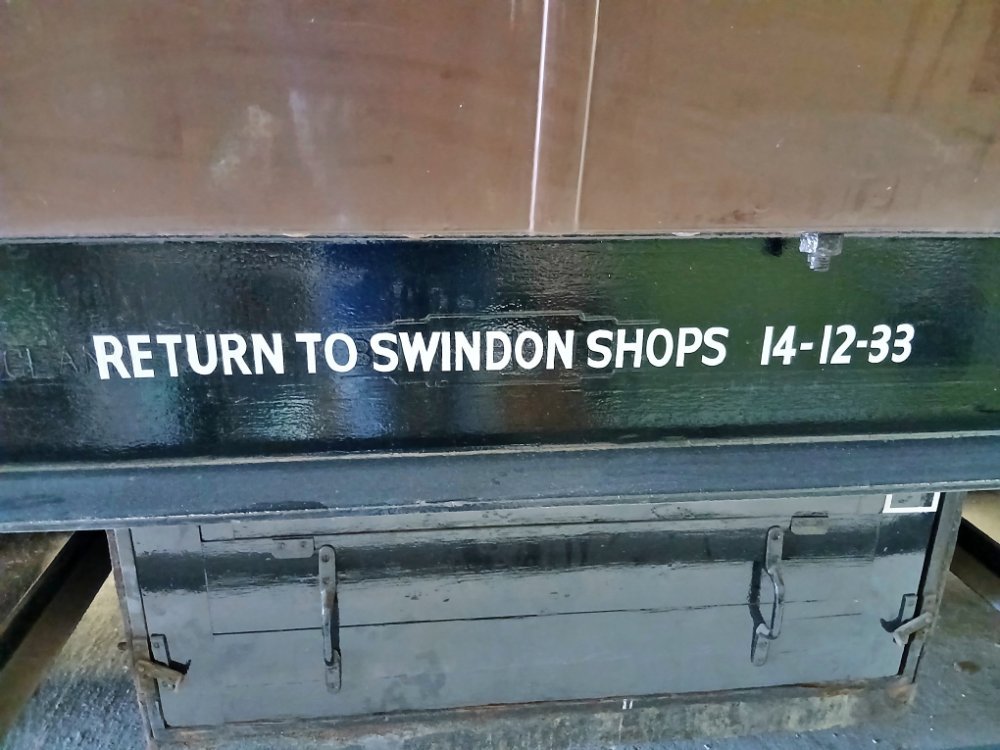

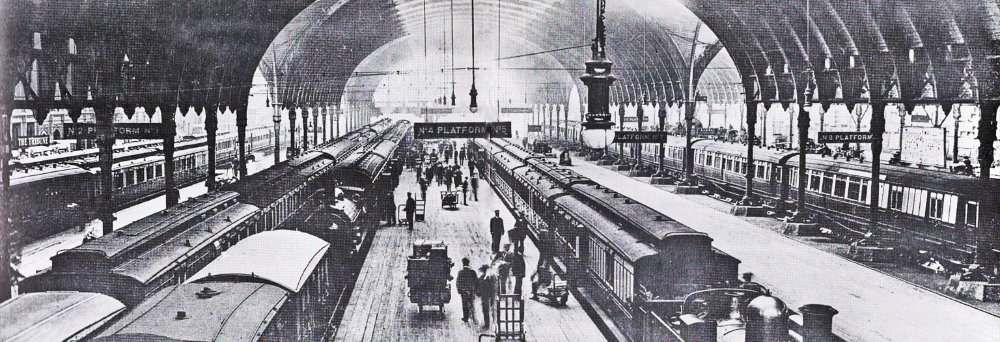

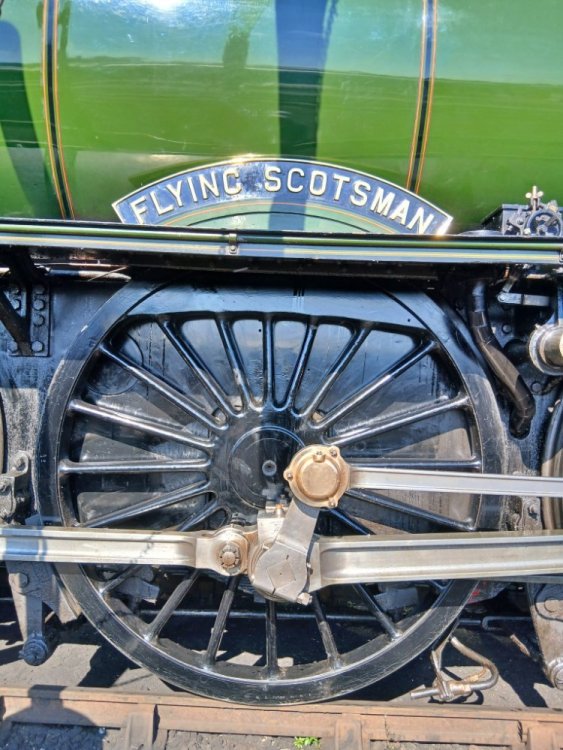

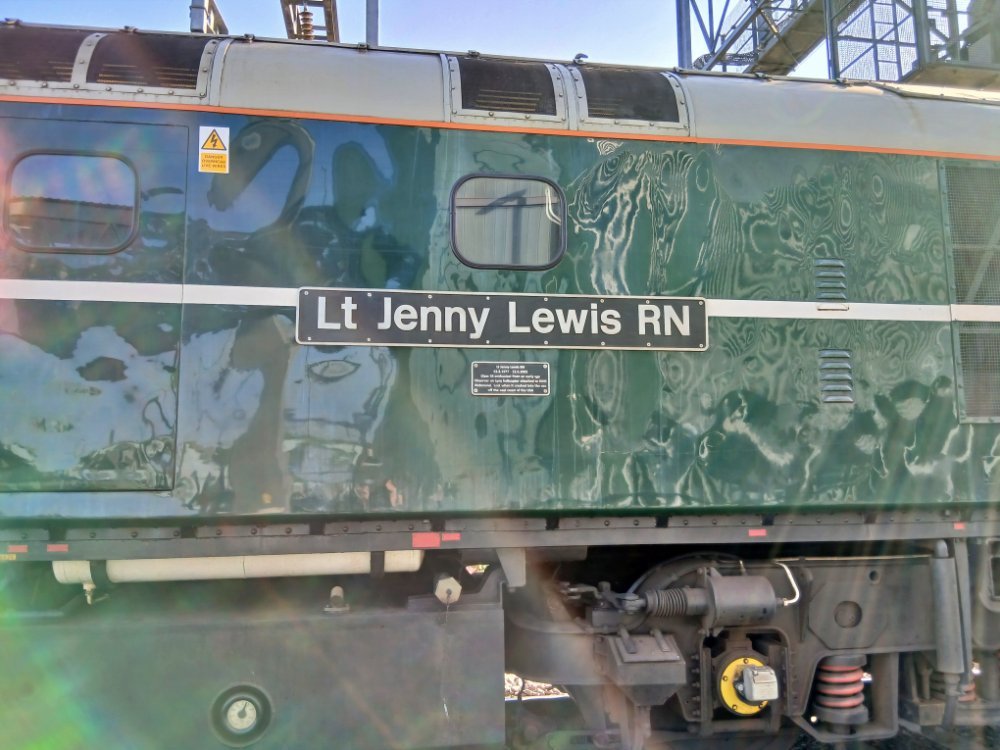

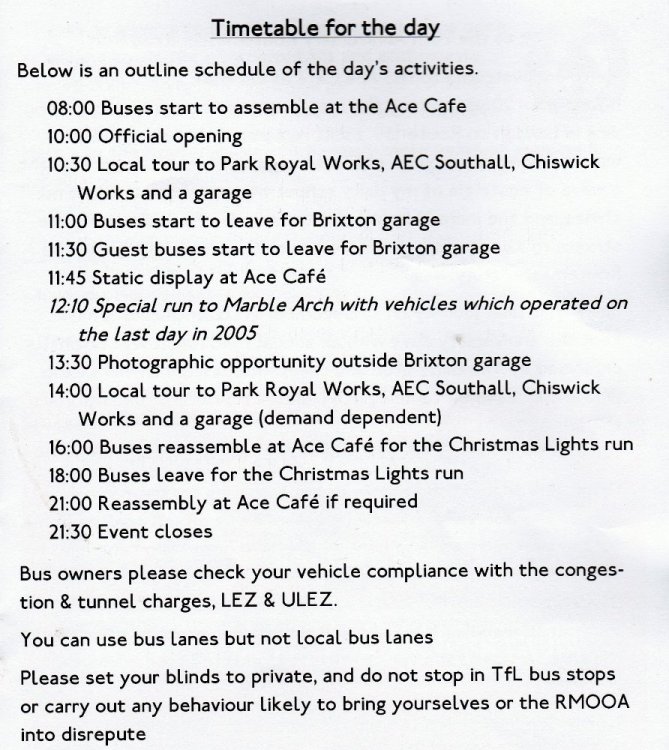

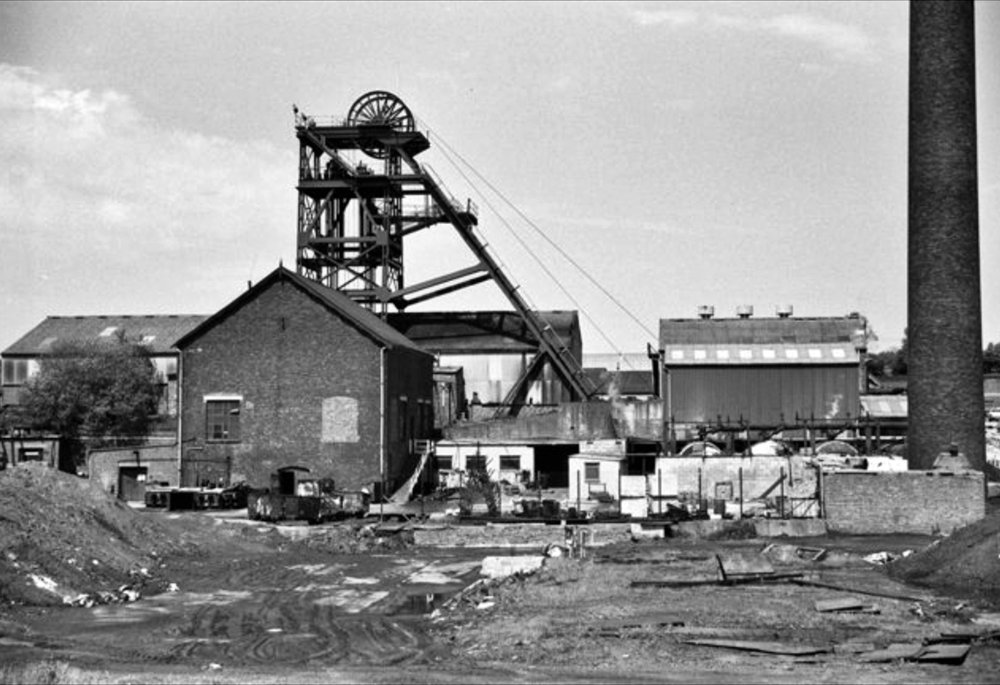

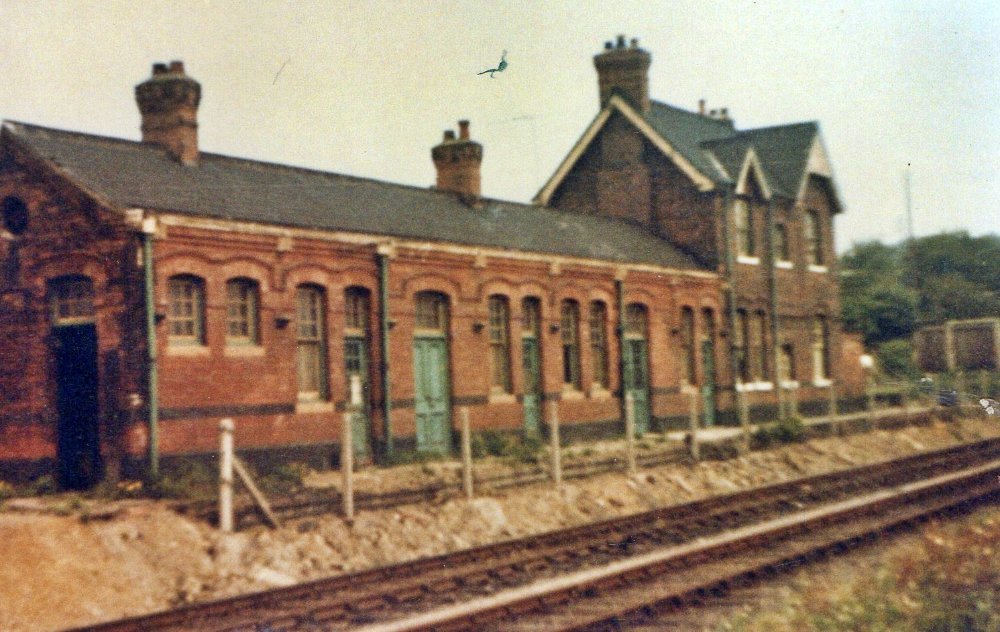

Hi there folks. Welcome to episode 8. In this one: Section 1: F2 pics from Cowdenbeath Section 2: Out and About 1 – Rivals Reunited at Didcot Section 3: Out and About 2 – The Driffield Truck Show Section 1 Cowdenbeath World Final Weekend – Saturday 6th & Sunday 7th September 2025 Macaroni Pie A new car which was finished in March finally debuted for Graeme Shevill Steven Burgoyne’s transporter The NI contingent: Shea Fegan Graeme Fegan Gavin Fegan Dylan Fegan Early weekend problems for Tommy Farrell Dennis Middler made a welcome return The ex- Adam Paling car Gerrit Huussen Bram Leenhouts in the ex-Leah Sealey car Grid walk time Ernie Burgoyne had refurbished the 2002 World Championship winning car of Chris’. It looked fabulous! This is how it was when I called in to the garage two years before! The WF top 3 trophies The defending World Champ interviewed by the grid girls Heart sunglasses B96 Guinchy outside pole Gordon on pole Nascar on the grid The grid was split pre-race for the intros A brief summary of the race: A clean first start with 7 keeping ahead of 647 who had passed 183 into the first lap. Caution flag for debris, and a stranded car in turn 3. Complete restart. No outside assistance. Drivers are allowed to get out to check their cars. A short-lived restart sees 674 up the turn 3 fence and landing on H124, with 127 also involved. 183 had moved ahead of 647. Another stoppage straight after the restart with 629, 618 and NI940 piled up in turn 4. 7 maintained the lead position. 7 maintained the lead until the end with 647 unable to challenge. 183 in third came upon a slow-moving NI998 down the back straight who applies the brakes. Charlie promptly spins him around and continues. Graham stays put. At race end as Gordon celebrates with doughnuts in turn two Guinchy stops next to NI998 on the back straight. NI918 who had retired rejoins the track and parks alongside creating a Fegan sandwich with a Guinchard filling. After many hand gestures the three part. Result: 7 647 183 16 547 1 880 15 H440 776 213 126 Gordon’s mum Evelyn joined the victory lap on the DPC truck Love it! A bit of work to do on H124 ‘The Flying Pig’ - Heritage F2 A good payout on the 50/50 for one lucky person on WF day Sunday morning repairs The 2025 World Champ interview Andy Smith dropped by for a chat Dylan Fegan raced Shea’s car on Sunday as the engine in his own was tightening up Ready for home A few days later Evelyn Moodie posted this: Well, it has taken me a few days to recover but I couldn’t let it pass without posting this World Champion – 5 Times! I am beyond proud to share that my son has just won the World Championship for the 5th time! To say it was special would be an understatement—it was emotional, unforgettable, and a moment our whole family will treasure forever. What made it even more poignant was that he won it at his home track, in front of his fans. As a wee boy, he watched his dad nearly win the championship there in 1990, coming second, and he always dreamed of putting #7 on that trophy. To see him achieve that dream brought tears to so many of us. I managed to watch the first start, but the nerves got the better of me, and I ended up sitting at the back (Kalms are useless, lol). The atmosphere was palpable, and by everyone’s reactions, I knew it was going to be close. When the place erupted, I knew he had done it! I watched it again on 24.7 TV—the coverage was phenomenal, and I highly recommend getting the replay, whether you were there or not. A huge thank you to Racewall, their staff, and everyone involved in putting on such a spectacular event. The organisation and effort that went into it must have been immense—they truly deserve every bit of credit. Oh, and that firework display would have impressed Disney The VIP hospitality tents were amazing. Watching the world finalists come through the tunnel, with fire flashes on either side and waving their country flags, being presented with personalised plaques, was special. And then the drivers parade lap being piped round by the two boys on the pipes, standing majestically high on the photographers’ platform, reminded me of the lone piper on the castle rampart at the Tattoo. Special thanks to Richard Kaleta, professional as ever in his Gold Jacket, and the photographers capturing these precious memories. A personal shoutout to Gareth Borthwick, my knight in shining armour, for helping me get on the back of the truck to celebrate the parade lap—it wasn’t an easy task, but he made it happen. The race itself—well, I wish I had watched it instead of being a nervous wreck! Every driver deserves credit, a few making history, especially our two incredible females from the Smith Dynasty—they have guts those girls but it’s in their DNA. To the fans—you were magnificent. The memory of that parade lap will stay with me forever. And lastly, hearing Gordon, his voice breaking with tears in his eyes, say: “All I ever wanted was to race a stock car, and I haven’t done too bad”… that moment will stay with me forever. "Congratulations, champ—you’ve made us all so proud!" Out and About 1 Rivals Reunited From 14 May to 2 June 2025, two legends of steam; Flying Scotsman and Pendennis Castle, brought over a century of steam-powered history roaring back to life at Didcot Railway Centre as they celebrated the 100th anniversary of their 1925 meeting. The historic reunion marked a special chapter in railway lore, as these two giants of steam have not just their iconic status in common but something of a shared history: both were exhibited at the British Empire Exhibition in 1925; both were once owned by the late Sir William (Bill) McAlpine in the 1970s and both have steamed in Australia in the 1980s. Now, they came together once more for an unforgettable celebration of British engineering and heritage. No 4079 Pendennis Castle In the 1920s, Great Western Railway's Pendennis Castle made waves when it was lent to the LNER for head-to-head trials with Sir Nigel Gresley's groundbreaking Pacific locomotives. Taking on 16-coach trains on the East Coast Main Line from King's Cross, this mighty Castle-class loco proved its mettle—outshining its rivals and earning the admiration of an entire generation. In 1925, Pendennis Castle was proudly displayed alongside Flying Scotsman at the British Empire Exhibition in Wembley. A cheeky sign proclaimed it to be ‘the most powerful passenger express locomotive in Britain’—and its performance certainly backed up the claim! No.4079 left England in 1977 for Australia, where she was looked after by the Pilbara Railways Historical Society. A highlight of the Australian sojourn was a visit to Perth in 1989 to operate alongside her old rival Flying Scotsman as the climax of a tour during the country's bicentennial celebrations. In 2000 Pendennis Castle was offered to Great Western Society and following a 10-week voyage finally regained British soil at Avonmouth. She has s since been fully overhauled and now regularly features at Didcot open days. The Global Star: Flying Scotsman What more can be said about Flying Scotsman, the most famous steam locomotive in the world? Designed by Sir Nigel Gresley and introduced to service in 1923, it quickly became a symbol of speed, innovation, and style. Named after the iconic daily London-to-Edinburgh service that began in 1862, Flying Scotsman achieved fame as the first locomotive to officially hit 100mph. Over the decades, it has captivated millions, becoming a global ambassador for Britain's railway heritage. She is now in the care of the National Railway Museum. Pics from the day: GWR Trolley This was used at Paddington for a very solemn purpose. Especially in and around London there were many Irish or descendants of Ireland who once passed away wanted to be buried in Ireland. The journey from London to Ireland by the GWR was via the ferry at Fishguard. Coffins were carried from London to Fishguard by train for their onward journey to Ireland. Rather than expose those passengers at Paddington to seeing a coffin being walked along the platform, this trolley was built to carry the coffin to the train undercover. 1942 Dennis Fire Tender formerly used at Swindon Works to protect the massive railway engineering complex. Cookham Manor As long ago as 1901 the traffic department of the Great Western asked for this type of locomotive. It was a very long time in coming, although the ‘Halls’ and ‘Granges’ filled the need except that they suffered route restrictions due to their heavier weight. The first twenty ‘Manors’, built before World War 2, incorporated the wheels and motion of withdrawn 43XX class engines. The last ten were built by BR in 1950. The 'Manors' were originally allocated to various English depots, but in 1943 several were transferred to the North Wales area, being the first modern passenger engines seen there. Detail design modifications over the years have greatly improved the performance of the class. Their light weight makes them ideal for use in preservation: no fewer than eight have survived. 7808 ‘Cookham Manor’ was built in 1938 and was withdrawn in 1965. She is the only ‘Manor’ obtained directly on withdrawal by BR. Bought by a Society member in 1965, she ran from Gloucester depot in steam to Ashchurch, where she was based with 6697, until they both came to Didcot in 1970. A very sprightly member of her class and held in high regard by crews, before withdrawal she had, very unusually for her class, been fitted with a larger 4,000 gallon tender. The remains of tank storage structures now used to store all sorts ODA 113026 21-ton, 2-axle 5-plank air-braked open wagon This vehicle was originally built as part of a large batch, constructed mainly at BR Wolverton, between 1949 and 1958, designated SOV and intended primarily for steel traffic. Some of these wagons were adapted for Ministry of Defence (MoD) traffic in 1983, by being fitted with air brakes and revised (UIC double link) suspension arrangements, at BR Shildon. Subsequent reduction in MoD requirements saw many of these wagons scrapped or put into departmental use. 113026 was in use by the Signal and Telegraph department and carried their red and yellow SATLINK livery. Most recently it has been stored out of use at Stafford, being delivered to Didcot in late December 2011. As an air-braked vehicle, it is approved for use on Network Rail and used to transport supplies between the west yard and the Railway Centre. The current Turntable is on the site of the 1932 Great Western one but is a replacement table, as the original had been removed by British Rail before the Great Western Society arrived at Didcot. The Turntable is 70 feet (21m) long and is capable of accommodating the largest tender engines. It is operated by hand either directly by pushing on extension levers or by operating a geared winding mechanism. The Class 31, or Brush Type 2, locomotive was one of the models ordered by British Railways to replace steam traction. 263 locomotives of this class were built by Brush Traction from 1957-62 and numbered in two series: D5500-D5699 and D5800-D5862. The first locomotive was completed at the end of September 1957 and entered service in November of that year. The diesel electric locomotives had a wheel arrangement of A1A-A1A 31270 entered service on 1 June 1961, originally carrying the number D5800 and allocated to March depot. It was withdrawn from mainline service on 30-May-2000. Since then the privately owned locomotive has been based at locations including Peak Rail, Colne Valley Railway, and most recently Nemesis Rail at Burton-on-Trent where it had been undergoing repair. It arrived at Didcot Railway Centre on 26 August 2023. 5227 The 5205 class were 2-8-0T locomotives designed for short workings from coal mines to ports in South Wales. They were a development of the 4200 Class introduced by the Great Western Railway in 1910. They retained the straight frames of the 42xx, but had outside steam pipes, and 19" diameter cylinders giving them slightly more power than their predecessors. 70 of the class were built, between 1923 and 1940 - 5205-5274. Twenty 5205s, 5255-5274 were converted to the 7200 Class in 1934/6 5227 was built at Swindon in 1924 and was withdrawn in 1962. She survived at Barry Scrapyard to become one of the 'Barry Ten', being the last unsold locomotives at Woodham Brothers in 1990 when Dai Woodham retired. The 'ten' were taken on by the Vale of Glamorgan Council and stored for another twenty years in scrapyard condition before being sold. The locomotive arrived at the railway centre in August 2013, to be used as a source of parts, principally the axleboxes for the project to build 47xx 2-8-0 No 4709. More recently it has been agreed that the boiler and pony truck will be removed from the locomotive and will be going to the Churchward County Project to provide a boiler for new build ‘County of Montgomery’, as originally set out in the 'Three Counties' agreement with Vale of Glamorgan Council. The remainder of the locomotive has been sold to an individual who intends to restore the locomotive to working order, including manufacture of parts to replace those removed for use in other projects. The locomotive is expected to remain at Didcot Railway Centre. 18000 is one of a pair of prototype gas turbine power engines ordered by the GWR from private companies but were not delivered until after the big four railway companies, as they were called, had been nationalised. 18000 was constructed by Brown Boveri in Switzerland and spent its working life hauling trains from Paddington before being withdrawn from service as uneconomic in 1960. The locomotives, as one-offs, were both unreliable and prone to failures and spent much of their short working lives in Swindon works either being repaired or modified. After with withdrawal 18000 was offered to the European Office for Research and Development and was moved back to Switzerland, where the gas turbine was removed and the locomotive modified to be an unpowered test bed. Once these experiments were concluded the locomotive was put on display outside the Mechanical Engineering Testing building in Vienna in 1975. The loco was eventually secured for preservation in the UK in the early 1990s and initially put on display at the Crewe Heritage Centre and after a spell at the GWSR was moved to Didcot Railway Centre in 2011. The loco has acquired the nickname 'Kerosene Castle'. In early 2022 it was announced that work would begin on a two-year conservation project to repair corrosion on the bodywork and return the locomotive to the black and silver livery it carried when first in service. The locomotive outside the shed shortly after arrival at Didcot Railway Centre - 30-Jul-2011 Official works photograph An artist's impression based on drawings supplied by Brown Boveri within their original tender No. 1 Cab Desk in original condition No. 2 Cab Desk - 30-Jul-2011 The engine space - 30-Jul-2011 No. 18000 as a Testbed for Research into Wheel-Rail contact At that time BR, and almost all other European railways, participated in the Office for Research and Experiments (ORE) of the UIC, the International Union of Railways. ORE sponsored technical activities of general interest to the railway industry, such as research and standardisation. The activities themselves were carried out by experts in the participating railways and certain other technical institutes. In those days the suppliers of railway equipment were hardly involved, they also had an entirely separate organisation to coordinate activities they considered relevant and useful. In the 1960s ORE had installed an international working party to investigate the parameters which influence the adhesion between wheel and rail. One of the themes to be researched was the effect of vehicle design parameters on adhesion. When 18000 became surplus to BR’s requirements a proposal was developed to convert her to a test vehicle in which a number of traction design parameters could be varied. 18000 was completely rebuilt in the Bellinzona workshops of the Swiss Federal Railways (SBB) for this purpose. Almost all of the original technical equipment was removed from the body and from the bogies. The wheel arrangement was changed from A1A-A1A to 1A1-3. That is, one bogie was fitted with one driving wheelset and two carrying wheelsets, the other was provided with three carrying wheelsets. The new driving wheelset and its associated test equipment required a major reconstruction of that bogie, and local remodelling of the vehicle body, leading to the ‘blisters’ on the underframe. It was possible to fit different types of traction motor, and to vary the axle load, transmission stiffness, sanding parameters, etc. The traction motor was fed by the equipment of another specially adapted locomotive, which ran in tandem. The choice of a suitable tandem locomotive made it possible to investigate the effect of different traction control systems and catenary voltages. Part of the original engine compartment of 18000 was occupied by the traction motor and mechanical transmission, which projected above the floor; the rest of the compartment was fitted out as a room for the measuring equipment, and for meetings of the test team. Trials with various traction configurations took place between 1970 and 1975. The test team was manned by personnel of the Vienna Mechanical Engineering Research Institute (where 18000 was displayed before being repatriated) and, as required, by traction experts of the SNCF, DB and SBB. BR played a major role in the statistical evaluation of the measured data. Interestingly, the test team affectionately bestowed the name Elisabetta on their unique vehicle, as a reference to her British origins. The photos were taken during a test run on the French-German border in late 1972. For these trials 18000 had been fitted with a Monomoteur type DC traction motor of the SNCF, which was fed by the thyristor traction equipment of the tandem locomotive of the SNCF series BB15000. The international character of the trials was underlined by the use of a multi-current DB locomotive (series 181) to haul the composition back to its starting position after each measuring run. 18000 during a test run on the French-German border in late 1972 The Didcot Transfer Shed Brunel originally built the Great Western Railway to his unique broad gauge of 7 feet between the rails as he thought this would give extra speed and comfort. But as the railway network expanded the Great Western had increasing problems with transhipping goods onto the standard gauge, or 'narrow gauge' as they called it, of the other railways and its broad gauge was finally abandoned in 1892. However, at Didcot Railway Centre the Great Western Society has recreated a section of broad gauge railway using materials recovered from a disused railway near Burlescombe in Devon together with the relocated Didcot Transfer Shed built in the 1850s to trans-ship goods between broad and standard gauge trains. Much of the recreated railway is laid as mixed gauge track, capable of carrying both broad and standard gauge trains. The view out of the shed Auto-trailer 190 Auto-trailer 190 was purchased in 1970 along with 92 and 212 (now restored to original condition as Steam Railmotor No.93). Its restoration started as early as 1971 but completion was going to be a long haul. The final result not rolling out of the C & W workshops until 1996. It is typical of the auto-trailers built in the thirties for the mass of branch lines that the GWR owned. Originally being hauled by the '517' class 0-4-2T locomotives, and later by 48xx/14xx 0-4-2T (the so called Auto-tanks), the 64xx 0-6-0PT locos, and lastly BR added Auto gear to the 45xx and 4575 classes. The interior (gutted prior to entering Departmental Service) has been completely re-created, using in part recycled oak, working mainly from photographic evidence. Some of the structural framing was made with timber from Wroughton Church when the structure of the bell tower was replaced with steel. The chair legs were made from off-cuts from the church oak and the rest of the interior furniture from new wood. The upholstery is a replica of the GWR 1937 pattern. 1340 ‘Trojan’ Trojan was built by the Avonside Engine Company of Bristol in 1897 (Works No. 1386) for Messrs Dunn & Shute of Newport Town Dock. She was purchased by the Alexandra Docks Railway in 1903, remaining unnumbered. This company owned around 100 miles of dock sidings in the Newport (South Wales) area, and a 'main' passenger-carrying line of 10 miles or so. On absorption of the Alexandra Docks Railway into the Great Western in 1923, ‘Trojan’ received the number 1340. She moved freely around GWR territory, and although based mainly at Cardiff Cathays and Radyr depots also worked for a time in Oswestry and Greenford, London. Withdrawn from Cardiff by the GWR in July 1932, she was sold to the Netherseal colliery at Burton-on-Trent, who passed her on to Alders (Tamworth) Ltd in 1947. After several years of negotiations she was finally released to one of the Didcot regular workforce arriving at the depot in April 1968. The locomotive has been under restoration for many years at Didcot. The main stumbling block has been the boiler, the original was in a very poor state and was scrapped at Didcot quite a few years ago. A substitute was purchased and sent to Chatham for modification. This job was never completed, and the stripped-down boiler was returned to Didcot and rebuilt on site. The locomotive entered traffic, for the first time in preservation, in 2002. With the expiry of the boiler certificate the locomotive was withdrawn from traffic in October 2011 and was overhauled once more, this time by Loughborough-based engineering company, Locomotive Maintenance Services. She returned to Didcot in March 2021 and is currently part of the operating fleet. No. 9113 'Prince of Wales' Eight ‘Super Saloons’ were built by the GWR to run between Paddington and Plymouth on the ‘Ocean Special’ trains in connection with the transatlantic liner services. Their construction followed on from experimental use of some Pullman coaches on the ‘Ocean Specials’ and a full Pullman Train – The ‘Torquay Pullman’ in 1929 and 1930. Hire of the Pullman coaches, with their attendants, was found to be too costly by the GWR, which consequently set out to design the finest coaches that they would ever build as a replacement. The Super Saloon design obviously owes a great deal to the 1929 Riviera Dining Cars having similar body shapes to the full 9’ 7” width allowed by the loading gauge and with similar recessed doors. Internally the carriages were equipped with fold-down tables and free-moving wing-back chairs. As was fitting for coaches used for such prestigious trains all were named after members of the Royal Family. 9111 ‘King George’ – Built 1931 – Preserved on the South Devon Railway 9112 ‘Queen Mary’ – Built 1932 – Preserved at Didcot Railway Centre 9113 ‘Prince of Wales’ – Built 1932 – Preserved at Didcot Railway Centre 9114 ‘Duke of York’ – Scrapped 9115 ‘Duke of Gloucester’ – Scrapped 9116 ‘Duchess of York’ – Built 1932 – Preserved on the South Devon Railway 9117 ‘Princes Royal’ - Scrapped 9118 ‘Princess Elizabeth’ – Built 1932 – Preserved at Didcot Railway Centre When Southampton became the major transatlantic port, boat trains to Plymouth declined both in number and prestige. As a result the saloons had to be found alternative work befitting their status and were often seen on special trains from Paddington to Newbury Racecourse in connection with race days as well as being used by private parties. The special stock was always kept at the bottom end of the Carriage Shed at Old Oak Common under the watchful eye of the coach inspector and maintained in immaculate condition ready for special journeys at short notice. Three of these coaches were preserved by the Great Western Society in 1966/67 and subsequently moved to Didcot in 1976. No. 9113 'Prince of Wales' is the third of eight built, and the first of the series to be fitted out by Swindon's Saloon Gang. Internally it is finished in French polished dark English walnut, with gold-leaf hairlines outlining the panelling. Structurally quite sound it is currently being substantially rebuilt so that it can be returned to service. To date the timber framework has been repaired and the vehicle has been completely repanelled. Current work is to refit the windows after which work will commence on returning the interior to as new condition. Dreadnought Once GJ Churchward was appointed GWR Chief Mechanical Engineer in 1902 he set about modernising the Great Western’s locomotives and rolling stock. The first major change in coach building came about with the introduction in 1904 of the ‘Dreadnought’ carriage. These, replacing the graceful but antiquated 50’ long clerestory coaches, with their 70’ length, 9’6” width and external doors only at the ends and in the centre of the coach, must have come as quite a shock to the travelling public. The ‘Dreadnought’ carriages could carry up to 72 passengers, compared to the clerestory’s maximum of 48. The nickname for this type of coach comes from ‘HMS Dreadnought’, a 527ft long battleship which entered service in 1906 and subsequently to the class of ships which followed. As the design was so revolutionary similar battleships built after her all became known as dreadnoughts, and earlier battleships as pre-dreadnoughts. The nickname is perhaps also indicative of a similar shift in technology on the railways. Unusually, the side corridor, changes sides half-way along the coach, possibly with the intention of better weight distribution. The Dreadnoughts were not popular with staff and passengers and only saw a few years service on the Cornish Riviera Limited before being replaced and relegated to less glamorous traffic. No. 3299 is a third-class coach built in 1905 as part of the last batch of Dreadnought coaches by the Birmingham Railway Carriage and Wagon company. It was built as a spare coach to fill in for maintenance on the main sets and to bolster summer holiday capacity. After being withdrawn from passenger use in 1951 it was used at Newquay as a dormitory for summer service catering staff. It was purchased by GWS member David Rouse, and gifted by him to the Great Western Society in 1964, becoming one of their first coaches. It was initially preserved at the Society’s base in Totnes, before coming to Didcot in 1967. The vehicle requires a major restoration, to which some thought is now being given. In 2022 the body was temporarily separated from the frames, so that the frames and bogies could be jet-blasted and given a protective coat of paint. A specific fund for the restoration of the Edwardian coaches, starting with the Dreadnought was launched in 2022. Paddington station in 1908 with a train of Dreadnought coaches at platform 8 on the extreme right and clerestory-roofed coaches at platform 5. Most of the other coaches in the photograph are clerestory roofed. Churchward thought big in both locomotives and coaches! This is 4-6-2 No 111 The Great Bear at the head of a train in which the first three vehicles are Dreadnoughts. No 3299 as first preserved in 1964 and parked on the cattle dock siding at Totnes. Between the left-hand door and the centre door is the corridor side with four compartments. Beyond the corridor crossover the five sets of three windows are the compartment side, with a droplight as the centre window in each set. The last window before the right-hand door is the lavatory. Phantom 08604 was shedded at Tyseley near Birmingham where one of the GWS volunteers, Simon Grego, was a fitter. The engine became well known as he repainted the loco in full BR lined-out green. She was withdrawn after shearing a crank pin key and had been purchased by a private individual from BR and the owner was looking for a place to keep it. Enter once again Simon. He made contact with the then Locomotive Manager, Richard Preston, who negotiated with the owner for the loan of the loco to the GWS and its movement to Didcot. Once at Didcot she required an extensive overhaul. One of the wheelsets had to be exchanged and the traction motor repaired, the engine had seized and had to be freed up, and the cab was devoid of some fittings which meant a partial re-wire. On the expiry of the loan agreement the loco was purchased outright by the GWS and now forms a very important part of the site's plant and equipment. The locomotive spent some time in a fictitious black war department livery with the number WD40, and then in the 'Tyseley' BR lined-out green, but in August 2010 she was repainted into an earlier plain green livery. In August 2017 the livery changed yet again, this time to BR Blue. She is now used for shunting the yard and sometimes works demonstration goods trains and very occasionally passenger trains at Open Days and Special Events. 1014 ‘County of Glamorgan’ The ‘County’ class of locomotives were the final development, by the GWR, of the 2-cylinder 4-6-0 locomotive, previous examples of which include the ‘Saints’, ‘Halls’, ‘Manors’, ‘Granges’ and ‘Modified Halls’. The first ‘County’, 1000 ‘County of Middlesex’ was outshopped from Swindon Works in 1945 and was effectively an enlarged Modified Hall, utilising the almost identical frames, cylinders and bogie, with larger driving wheels, and a larger boiler based on the Stanier 8F design but with a much higher pressure. A total of 30 County Class locomotives were built between 1945 and 1947, and re-used most of the names originally used for Churchward’s earlier 4-4-0 County class, the last of which was withdrawn from service in 1933. The last of the class, No 1011 County of Chester was withdrawn in 1964 and all were scrapped. GWR 2-cylinder 4-6-0 development is well represented in preservation with several examples of Halls (such as 5900 ‘Hinderton Hall’), Manors (such as 7808 ‘Cookham Manor’) and Modified Halls (such as 6998 ‘Burton Agnes Hall’). However, missing from the list were the Churchward Saint class, Collett’s Grange class, and Hawksworth’s County, none of which survived into preservation. The Great Western Society has constructed a new Churchward Saint - 2999 ‘Lady of Legend’, and the Betton Grange Society have repeated the process by completing their locomotive No 6880 Betton Grange leaving a ‘County’ as the missing link ... 1014 ‘County of Glamorgan’ - David Bradshaw, a GWS member, instigated a proposal to remedy the missing County. He calculated that amongst the last group of unrestored locomotives, once stored in Woodham's scrapyard at Barry, were sufficient standard parts to form a basis for a County - with minor modifications and some new-build components. After a long gestation period the G.W. County Project was launched in 2005 to recreate a Hawksworth ‘County’ 10XX 4-6-0 at Didcot, utilising the frames of Modified Hall 7927 Willington Hall, and a Stanier 8F boiler from 48518, from which the original County boiler was derived. Marking the contribution of Vale of Glamorgan Council and Barry scrapyard, it was agreed the completed locomotive should bear the identity 1014 ‘County of Glamorgan’. The original locomotive of this name was withdrawn in 1964 and scrapped at Cashmore's in Newport. Shortly before Christmas 2004 agreement was reached with the Vale of Glamorgan Council and the Heritage Lottery Fund for the Great Western Society to acquire the frames of ‘Modified Hall’ 4-6-0 7927 ‘Willington Hall’ and the boiler from Stanier 8F 2-8-0 48518. After the initial frame conversion work had been carried out at Llangollen, the chassis was moved to Didcot where all subsequent construction has been carried out. Since the launch, the frames of 7927 have been altered to the County pattern, a new set of 6’3” driving wheels cast and fitted and a new cab and splashers have been manufactured and fitted. New motion has been produced, and outside coupling and connecting rods, slidebars, and crossheads have been forged and fitted. A new tender has been made to the original Hawksworth design and is close to finishing. The boiler has had the firebox overhauled and a new barrel and smokebox fitted, and it was planned to be returned to Liverpool for HBSS to complete it. Whilst it is away the inside motion, lubrication system, superheater header and a multitude of other components will be made ready for fitting when the boiler returns. A number of items have been saved from dismantled Counties, including the double chimney from 1006 County of Cornwall, the regulator handle from 1014 County of Glamorgan, and the reverser wheel from 1013 County of Dorset. 5322 Introduced to fill an urgent need for a general-purpose type, the 53xx were an immediate success, and the fact that 342 were built (after 1932 with side-window cabs) is a measure of their usefulness. They served throughout the GWR system. From 1936 to 1939 one hundred were withdrawn and the wheels and other parts incorporated in new 'Grange' and 'Manor' engines. Withdrawal of life-expired class members started in 1948, but some remained almost until the end of steam. 5322 was one of twenty GWR 2-6-0s built in Swindon in 1917, during the Great War, and sent when new to France. This was in response to a call from the army in the summer of 1917 for the British railways to supply a further 160 locomotives to help with transporting supplies from the Channel ports to the front line. Frank Potter, General Manager of the GWR, reported at the time to his board of directors that these locomotives, “should as far as practicable be of one type, i.e. 0-8-0, and of high power, and arrangements were therefore made for them to be supplied by as few Companies as possible, these Companies in turn being allocated engines from the stock of other Railway Companies. In the case of the Great Western Railway, we have no engines of the 0-8-0 type, and it was impossible to release any of the 2-8-0 class as they are employed exclusively on the Admiralty coal traffic.” It was therefore decided that the GWR would supply 2-6-0s, which Frank Potter explained: “The Great Western type of 2-6-0 engines is in point of power and efficiency practically equal to other Companies 0-8-0 engines”. Nevertheless, the GWR drove a hard bargain, as Frank Potter continued: “The whole of our stock is, however, badly needed for traffic work in this country, and it was, therefore, stipulated that the materials should be supplied by the Government to enable new engines of the class to be built, an output of five per month being aimed at.” A serving officer with the ROD, C E R Sherrington, recalled an encounter with 5322 in France in 1918. He wrote an article about it for the Great Western Echo in 1973: “That night nearing the level crossing at Pont des Briques, where one turned off for the Mess, an eastbound train was rapidly overtaking me. A glance at my watch led me to hope that it was RCL* 21 running on time from Calais (Rivière Neuve) to St Omer, Hazebrouck and one or more railheads. There was no mistaking the type of locomotive – by the beat of its exhaust – a GWR Mogul, thus confirming that it was, almost certainly, one of the 53s doing such splendid work on those supply trains for the II Army. She overtook me at the Pont des Briques crossing, with its metal rolling gates, and it was easy to see her number in large white letters on the tender – ROD 5322. Behind her were the customary 44 or so wagons, the supplies for two divisions. The gross load was some 770 tons: the wagons were not vacuum fitted, but, of course, had the French screw couplings. The Great Western Moguls were admirable locomotives for this work: their predecessors on it, the Beyer Peacock 4-6-4 tanks, which were built for the Netherlands but never got there, were splendid machines but had inadequate brake power, being designed for suburban passenger trains. The LNWR class 27 0-8-0s, though fine pullers, had small diameter wheels for this work, and were more suited to heavier, slower, trains.” * RCL stood for Ravitaillement Calais Ligne The saying ‘Old Soldiers never die’ was never truer than with this engine. Demobbed in 1919 at Chester, she was withdrawn from Pontypool Road depot in April 1964. Miraculously, as the sole surviving early 53xx sent to Woodham Bros of Barry that avoided the cutter's torch, this gem was spotted there, and by 1969, after considerable persuasion needed to secure its release, she was acquired by a Society member. The first ex-Great Western locomotive to leave the scrapyard for preservation, she was towed to Caerphilly in 1969. There, a small but devoted band of members of the Society's South Wales Group restored her, in the open, to working order. The move to Didcot took place in 1973, she continued to be used on open days until around 1975 when she was stopped for various reasons. The owner at that time believed that items of historical value should not be restored, but maintained in the condition they are in. This meant that the engine stood as she was, static display only. The locomotive then passed into the ownership of the Society, and a fund was started to restore the engine. Thus, since the early 90s various bits have been overhauled, the cab was completely refurbished, the wheels and motion have been tended to, the boiler has been removed, and the tender stripped down. Slowly the engine was returned to its 1919 appearance until she was finally ready to return to traffic in November 2008. In November 2011 the locomotive was disguised as a Russian locomotive and starred in a film version of Anna Karenina. In May 2012 she was turned out in BR black livery. The locomotive was withdrawn in Summer 2014 with boiler problems. Western Fusilier When British Railways was formed, the western region fought to keep the independent spirit of the Great Western alive. Whilst other regions primarily used electric transmission Swindon developed a fleet of diesel locomotives with hydraulic transmission. There were three larger bogie arrangement classes; Warships, Hymeks, and Westerns, and one smaller 0-6-0 class, most of which were built at Swindon works by former Great Western staff. The largest and most powerful of the fleet were the C-C Class 52 ‘Western’ diesels powered by Maybach engines with Voith transmission. Although the class were successful, their lives were always going to be short as they lacked Electric Train Heating (ETH) which was becoming standard with the introduction of more modern coaching stock. The class were moved onto freight traffic before being withdrawn in 1977. D1023 “Western Fusilier” was built at Swindon in September 1963 and was withdrawn in February 1977 having operated various runs including the last ever Western hauled rail tour = the ‘Western Tribute’. In 1973 she was the last ever hydraulic to have a general repair at Swindon. The loco was preserved as part of The National Collection and was placed on display in the National Railway Museum (NRM) at York in 1977 and has been in the museum’s care ever since. The locomotive has been placed on loan to Didcot Railway Centre for a period of five years commencing January 2023. The locomotive is not operational and the NRM has no plans to put it into working order. Burton Agnes Hall A continuation of Collett's numerous and highly successful ‘Hall’ class, the ‘Modified Halls’ incorporate improved features introduced by his successor F W Hawksworth, as a prelude to his own new designs intended for post WW2 service. They ran throughout the Great Western system, and many survived until the end of BR Western Region steam. For some time after nationalisation of the railways in 1948, the newly formed BR continued construction of certain of the established designs of the absorbed companies. The ‘Hall’ class was one of these, building of which was not completed until the end of 1950. 6998 ‘Burton Agnes Hall’ emerged from Swindon Works in January 1949, going initially to Cardiff's Canton depot. She survived until withdrawal by BR from Oxford in January 1966 after being honoured as the engine chosen to work the Western Region's last steam-hauled passenger train. In markedly better condition than the other survivors, she was selected by the Society to represent the typical two-cylinder Great Western tender locomotive, no others at that time being expected to survive. The locomotive was purchased by the Great Western Society in January 1966 for the sum of £2,500, and on 2 April worked light engine under her own steam from Oxford to the Society's Depot at Totnes via Didcot, Reading West, Newbury, Westbury, Taunton, Exeter and Newton Abbot. She remained at Totnes until the end of 1967 when she worked an epic railtour from Totnes to her new home at Didcot on 2 December that year, hauling No. 1466 (also in steam), Dreadnought No. 3299, all third No. 5952, and auto-trailer No. 231. At Didcot the locomotive has been in virtually continuous service, also with plenty of main line and preserved railways use, ever since. She was withdrawn from service in 1996 and is stored complete awaiting its turn in the queue for overhaul. Drysllwyn Castle Designed as a more powerful, updated version of Churchward's renowned ‘Star’ class of 1906, the ‘Castles’ were an immediate success, and achieved an enviable reputation for speed during the interwar years on such trains as the one-time world's fastest, the Cheltenham Flyer. A total of 171 ‘Castles’ were in service by 1950, which included 25 converted from 'Stars' and one from ‘The Great Bear’, Britain's first 4-6-2 (Pacific) wheel arrangement engine. Eventually displaced by dieselization, eight engines of this class survived into preservation. Most were named after castles in the Great Western's territory, 12 after second world war aeroplanes, and 24 carried miscellaneous names. In 1937 it was decided, some say demanded, by certain Earls that new small engines intended to carry their names should not do so, instead 21 ‘Castles’, between 5043 and 5063, were commandeered and re-named. 5051 ‘Drysllwyn Castle’ was built at Swindon in May 1936. She was renamed ‘Earl Bathurst’ in August 1937 and carried that name for the rest of her GWR and BR life. Both names are regularly used on the locomotive at Didcot. Stationed almost exclusively at Landore (Swansea) depot, for working to London and the Midlands, she was rarely seen elsewhere. Withdrawn by BR as surplus to requirements, from Llanelly depot in 1963, she was sent for scrapping to Woodham Bros. of Barry, from where it was rescued by a Society member, and brought to Didcot in February 1970. Out shopped in 1980 she took part in the Rocket 150 celebrations at Rainhill in May of that year. She then ran many main line specials in the early years with Didcot's vintage train until 1986 when the main line ticket ran out. The engine then ran at Didcot until the boiler certificate ran out in 1990. Following a second overhaul she was returned to service, and enjoyed runs out on the mainline once more, and visits to other preserved railways as well as Didcot duties. In 2008 the latest boiler certificate expired and the locomotive is now on static display until such time as a further overhaul can take place. Diesel Railcar 22 The GWR built 38 Railcars between 1933 and 1942. The earliest batch of railcars proved very popular with passengers, and so later batches were fitted with standard buffers and drawgear. This allowed the railcars to tow a coach behind them at peak periods and also allowed them to act as the local pick-up goods train during off-peak periods - these railcars could often be seen with one or more goods vans in tow on the branch lines. The final four GWR railcars were built as single ended versions with a pair operating back-to-back, or as a three car unit with a coach sandwiched in the middle - these were the ancestors of the Diesel Multiple Units. Number 22 was built in 1940. Accommodation is provided for passengers in two open saloons with a total of 48 seats, and there are driving cabs at each end. It is powered by two AEC 9.6 litre, direct injection 6-cylinder engines through a Wilson epicyclic gearbox. The engines are of very similar specification to those used in London Transport buses for over 50 years. Externally it has been almost completely repanelled and last underwent a complete repaint in 1992/93. The Railcar entered service from Newport shed on 18 September 1940. She was allocated to a number of different sheds, including Reading, and during her later days she worked around the Worcester area and frequently ventured onto the Severn Valley line. She was withdrawn from service in 1962 and stored at Swindon, from where she was bought by the Midland Group of the Great Western Society for preservation in 1967. She initially worked on the Severn Valley Railway before coming to Didcot in 1978. Number 22 is one of only three GWR railcars to survive into preservation and is currently the only operational example. Number 4 (one of the earlier streamlined versions known as the ‘flying bananas’) is preserved as a static exhibit at STEAM - the Museum of the Great Western Railway, while Number 20 (one of the same batches as Number 22) is currently undergoing restoration at the Kent and East Sussex Railway. Pendennis Castle was used to push the Flying Scotsman back into the shed: Alongside Drysllwyn Castle Burton Agnes Hall joins in Pendennis Castle heads to the ash siding Trojan is ahead The view halfway up the coal stage ramp The incline to the coaling stage Inside the coaling stage After leaving the event: On the mainline was BR Class 33, D6515 (also known as 33012 and named "Lt Jenny Lewis RN") owned by the 71A Locomotive Group and based on the Swanage Railway. As of July 2025, the locomotive has been utilized by Hanson & Hall for freight services, which included traversing the wider area. A number of Class 66s were at Didcot Parkway Out and About 2 The Driffield Truck Show Truck It brings together vintage trucks, custom art-painted builds, fleet displays, and thousands of passionate enthusiasts. Enjoy the pics of some stunning vehicles: # Next time: In the last one of this off-season we have a Ticket to Ride: and a walk around the area of an abandoned Nottinghamshire colliery:

-

4

-

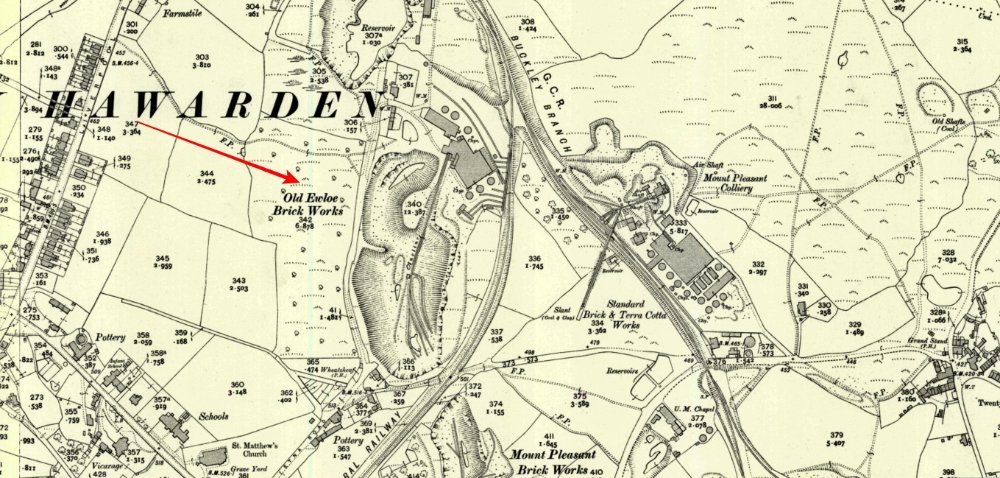

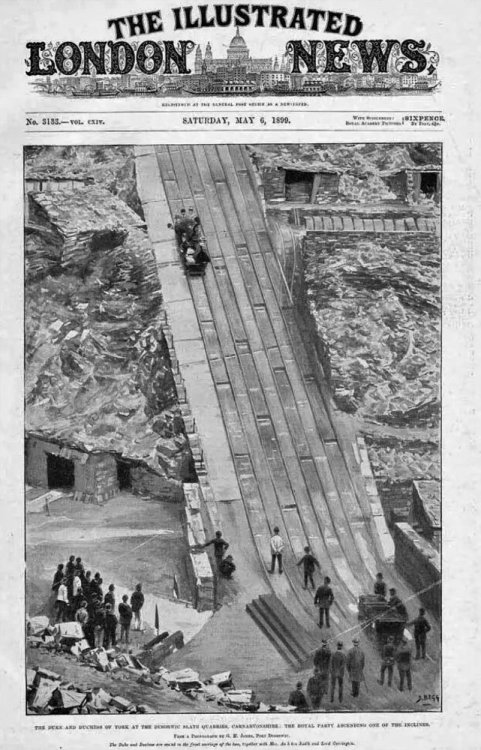

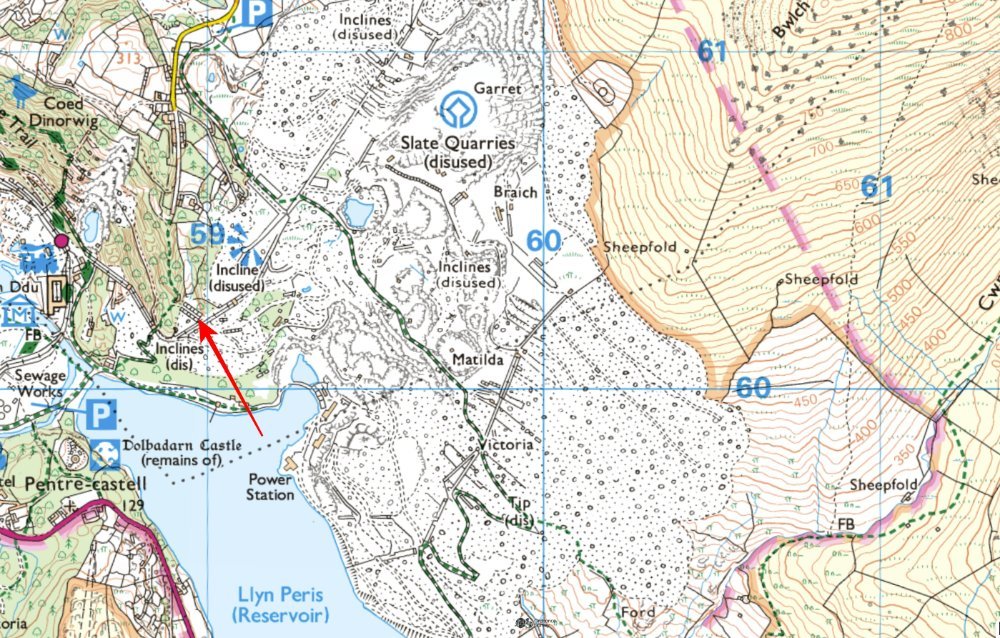

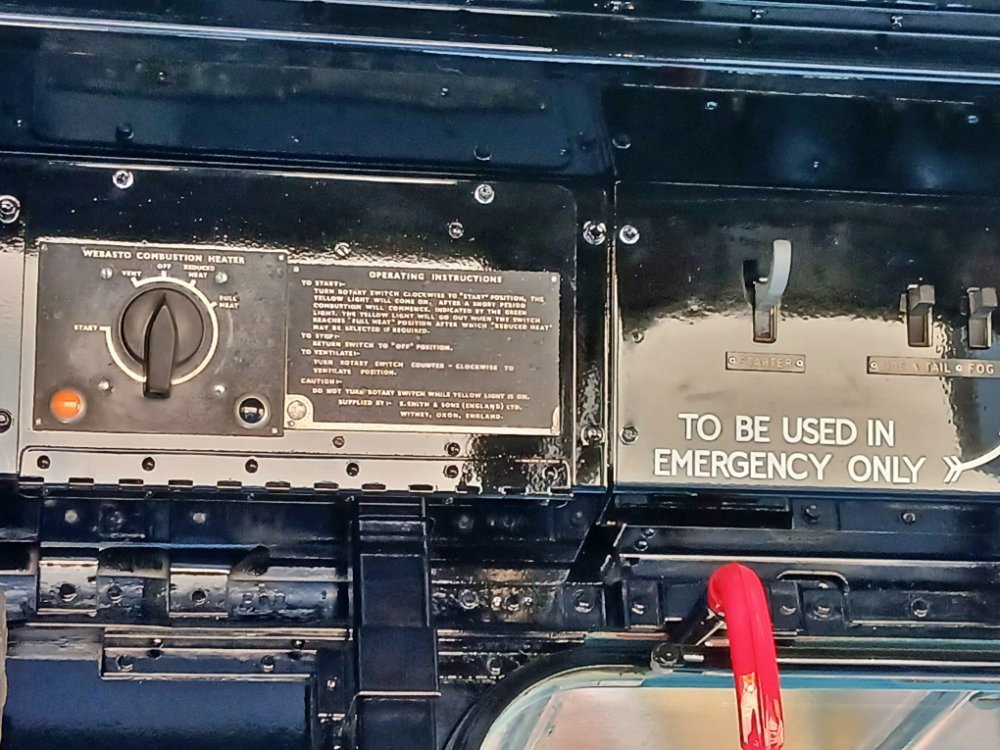

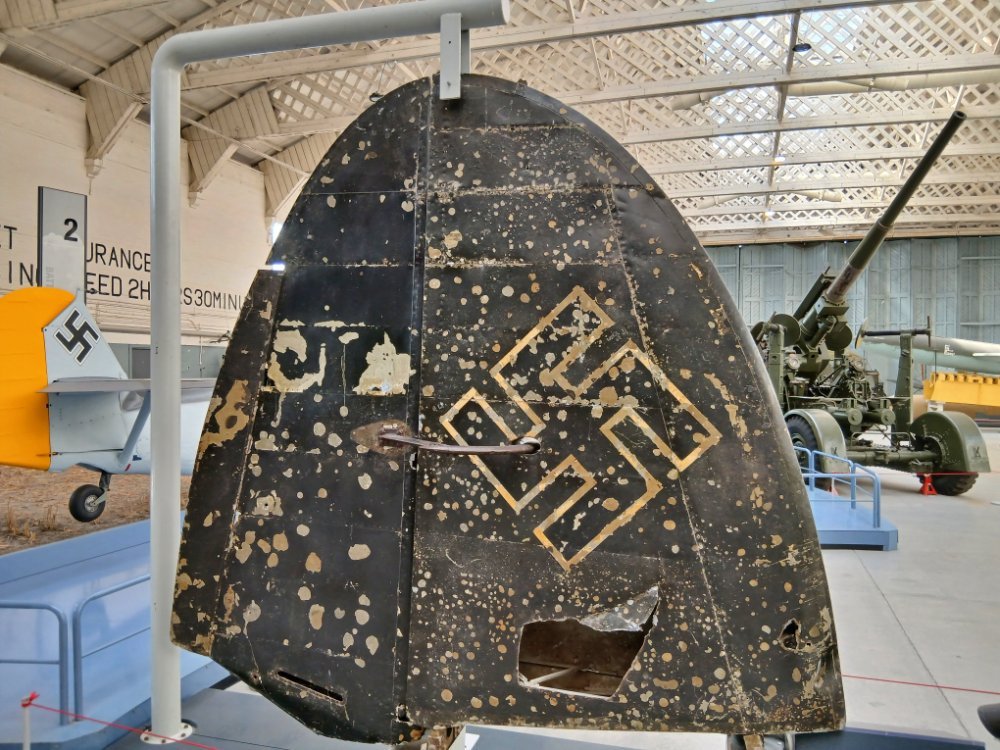

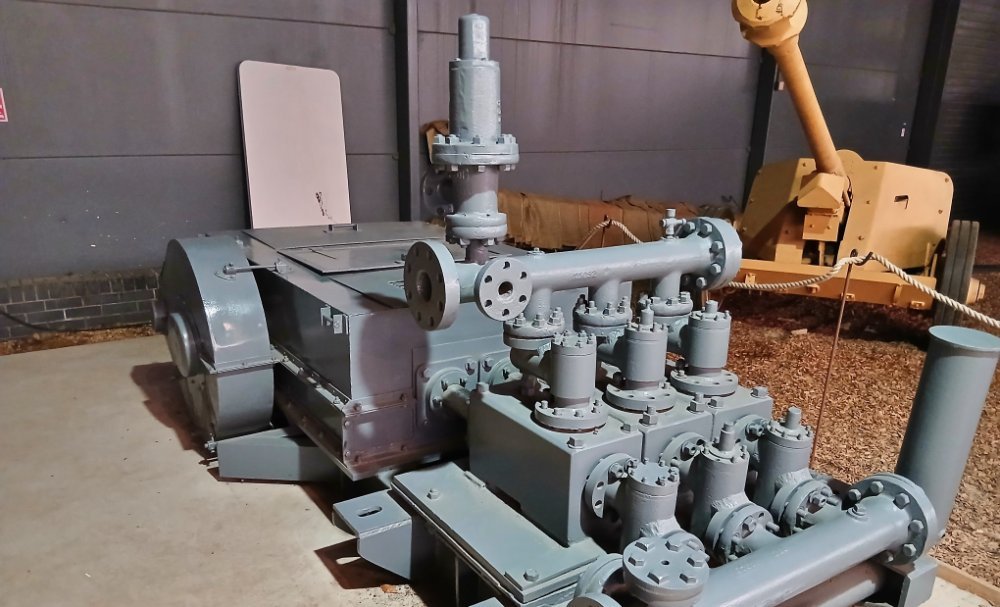

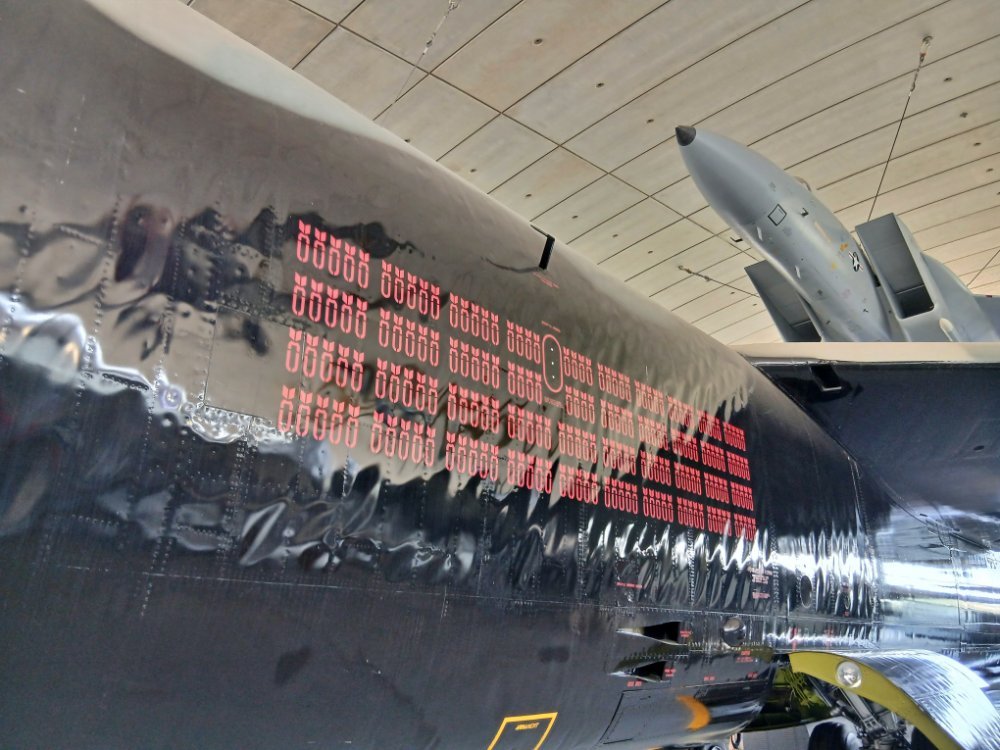

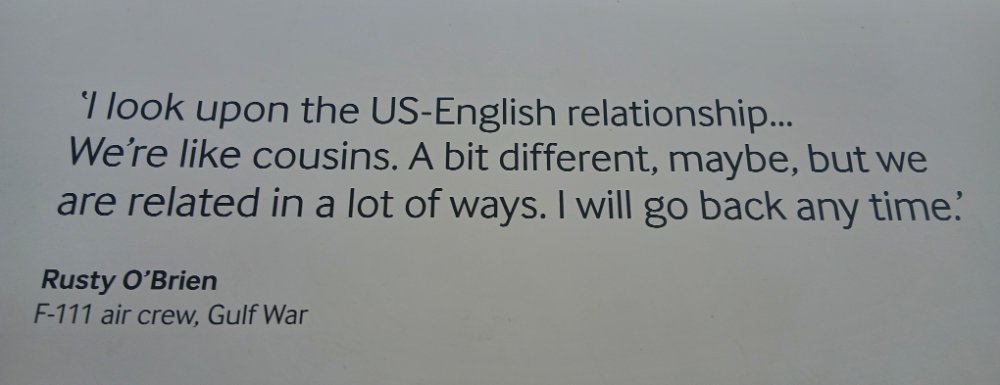

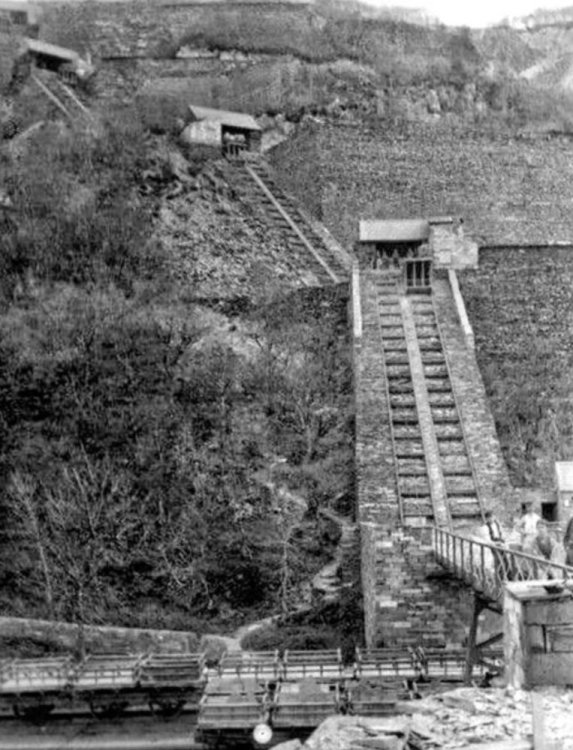

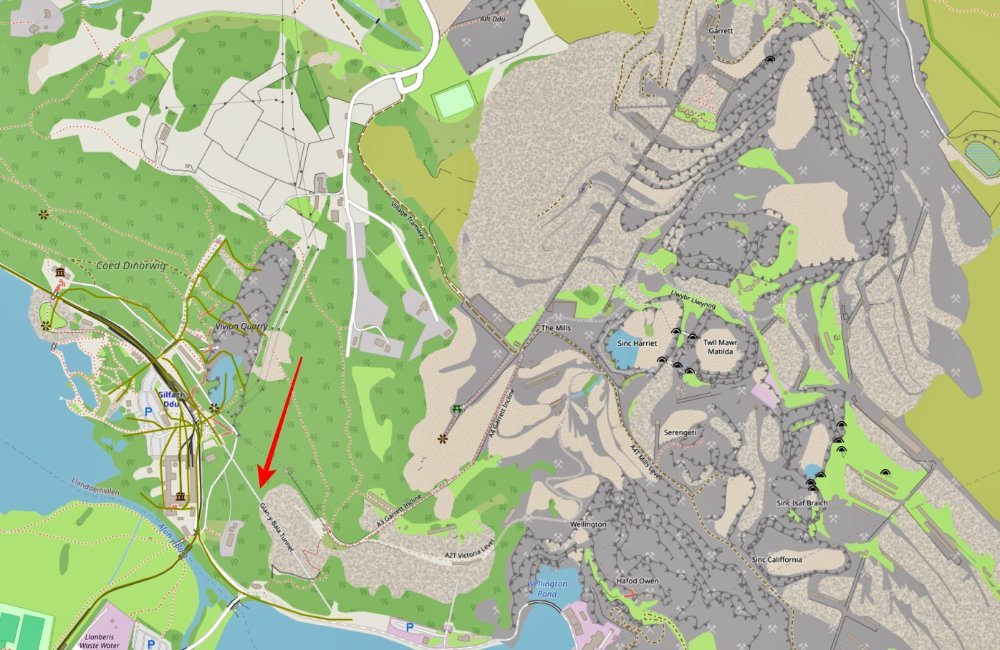

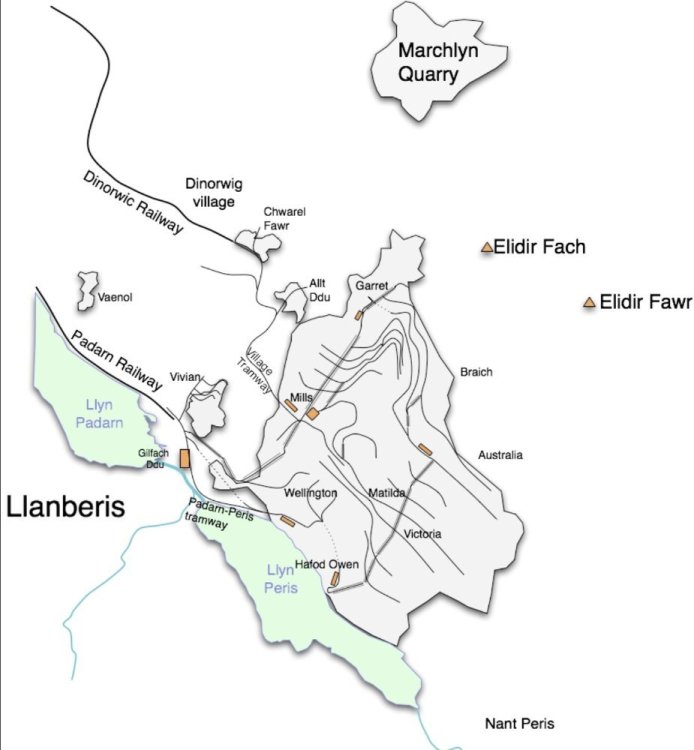

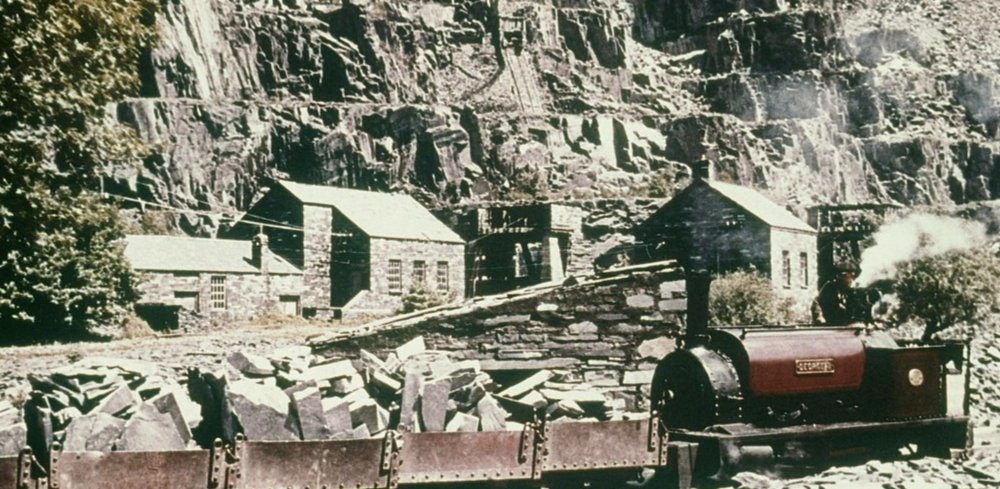

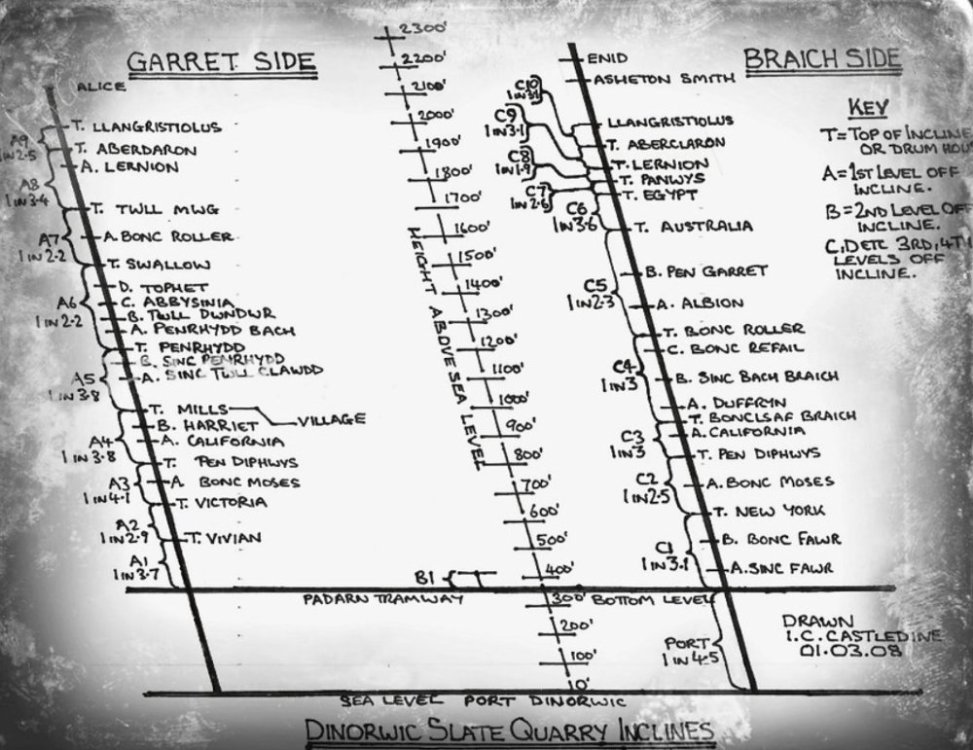

Hi there folks. Welcome to episode 7. In this one: Section 1: F2 pics from Taunton Section 2: Out and About 1 – Dinorwic – Part 2 Section 3: Out and About 2 – Duxford on BEA 2 Section 1 Taunton Saturday August 23rd 2025 – World Championship Semi-Finals A terrific turnout of 80 BriSCA F2 Stock Cars were in action for the World Championship Semi-Finals as they returned to Smeatharpe Stadium for the first time in 16 years. The O’er the Border Trophy, Nostalgia Trophy, and Chequered Flag Trophy were also up for grabs on a night featuring a deluge of silverware. The first Semi-Final was particularly hit by withdrawals, allowing eight reserves to join the grid behind the 20 remaining qualifiers. A fine start by polesitter 183 Charlie Guinchard put the silver top into a clear lead while second and third qualifiers 674 Steven Burgoyne and 213 Tom Bennett both lost ground as they took to the outside line to avoid a spun 461 Tom Davison. That allowed 1 Luke Wrench and 776 Dan Roots to jump into second and third from rows four and three, respectively. 547 Lewis Burgoyne and 992 Harley Burns slotted into fourth and fifth as the elder Burgoyne, 355 Aidan Grindey and Bennett all dropped into the lower half of the top 10. Further back, home star 127 Matt Stoneman was making rapid progress from 19th on the grid. He had broken into the all-important top 10 within the opening five laps. Despite his difficult start, Steven Burgoyne had plenty of pace in his car, and he picked off Burns and his nephew Lewis to run fourth before half-distance. The top three of Guinchard, Wrench and Roots were well spaced as the race settled down, but with plenty of backmarkers to deal with, they could not ease up. Roots was first to suffer in traffic, sent into a spin after an intervention from 564 David Shearing. Second-placed Wrench then got hooked up with 239 Michael Johnston and was fortunate that a wallop from Shearing helped separate them without him losing position. Roots’s drama promoted Steven Burgoyne to fourth and the charging Stoneman to fifth, while Bennett took sixth as Lewis Burgoyne got crowded out and shuffled back. Guinchard had effectively checked out, but in the closing few laps he found the backmarkers increasingly difficult to deal with – much to his chagrin. He perhaps didn’t realise that such was his pace, he was now among the cars that were in an almighty scrap for the final qualifying places and none were going to give an inch as they traded hits. Guinchard had enough in hand that he could exercise caution where needed and still take a relatively comfortable win, from Wrench, Steven Burgoyne, Stoneman and Bennett. Burns broke free of the massive battle behind to finish sixth ahead of 618 Ben Lockwood and Roots, who did well not to lose more ground in his earlier moment. 880 Jack Witts, who joined the field as a reserve, and 155 Archie Grindey just got the better of 184 Aaron Vaight to grab the final two qualifying places. Another four reserves joined the grid of Semi-Final 2, which began with a pile-up extinguishing the hopes of local star 24 Jon Palmer and one-time world champion 101 Kelvyn Marshall, along with 411 Reece Winch. Out front, 7 Gordon Moodie was as much in command as Guinchard had been in the previous race. Outside front-row man 100 George MacMillan Jr had managed to get to the inside and slot into second ahead of fellow Scot 647 Chris Burgoyne. The three began to close up as they dealt with traffic and it was MacMillan who lost out as he tangled with 605 Richard Andrews. That promoted 915 Jamie Jones and 463 Ryan McGill into the top four but they were some way adrift of the multiple world champions out front. Moodie was largely untroubled en route to his seventh semi-final win in the past eight editions and Burgoyne was also comfortable in second. McGill tracked Jones for most of the race, unwilling to take too big a risk until the final bend; when he did make his move, it didn’t pay off, so Jones took third and McGill had to settle for fourth. 3 Liam Rennie got the best of a good scrap with 16 Craig Wallace and 667 Tommy Farrell to finish fifth. Having lost ground early on, 931 Rebecca Smith latched onto the trio, and when Farrell got turned into the wall exiting turn four, she was able to benefit. Smith came through to sixth, securing her World Final debut. Wallace was seventh, ahead of fellow Scot 629 Euan Millar. 126 Jamie Avery and 186 Kasey Jones completed the qualifiers. The meeting final takes on extra significance on Semi-Finals day. Not only did it carry the O’er the Border Trophy, it would also decide which semi-final’s qualifiers would start on the inside line for the next month’s World Final at Cowdenbeath. Thirty-four of the 38 qualifiers took up their places, with coloured ribbons carried by the World Finalists to signify which semi they had qualified from and, therefore, which ‘team’ they were on. Any hopes that Guinchard had of securing pole position for himself, without needing the assistance of others, were soon ended when he was pushed wide by Wrench and retired with a puncture. Rebecca Smith was also a victim of the frantic scrambling for places as she thundered into the Honiton bend wall with 890 Paul Rice and ended up on her roof. McGill had just taken over from long-time leader Purdy at the time, with the impressive Winch following through into second. As McGill raced clear on the resumption, Avery pushed Winch wide to take second but could not catch the flying Scotsman in front. McGill took the win from Avery and Winch with Moodie making it three drivers from SF2 in the top four, but ultimately he had McGill to thank for securing him pole position for the World Final. (The above report with credit to Crispen Rosevear) Results: Ht.1 844 Ht.2 (SF1) 183 1 674 Ht.3 (SF2) 7 647 915 CONS 1 727 CONS 2 411 Final 463 126 411 GN 390 A few of the many cars in the pits: Steven Gilbert Alfie Brimble John Hogg Mika Millar Charlie Fisher Phil Mann Neil Hooper Chris Burgoyne Connor Blake Liam Rennie Ryan Sheahan Gary Kitching Reece McIntosh Sy Harraway Jason McDonald Adam Langridge Gordon Moodie Gary Walker Team Burgoyne The line up for practice Buster had recently won the Irish Open Championship in the Saloons Two very smart Scanias Info for the drivers Results: Ht.1 844 Ht.2 (SF1) 183 1 674 Ht.3 (SF2) 7 647 915 CONS 1 727 CONS 2 411 Final 463 126 411 GN 390 Out and About 1 Dinorwic – Part 2 We continue our look around this magnificent site: The Duke and Duchess of York paid a visit to Dinorwic in 1899. The caption mentions them ascending one of the inclines. A commemorative plaque survives on this old doorway We are making our way to the lodgings for the men who did not live locally A few ruined buildings from an earlier time before the quarry existed are encountered An upside-down truck slowly being consumed by nature With a drum house in the background this lookout building was an ingenious use of the slate. With the slanted opening It enabled a clear view of approaching trucks on the tramway. A huge slate slab overhang would help to keep the rain off. A set of points at the base of the nearby incline Twin tracks We have arrived at Anglesey Barracks The barracks arrowed on the map Dinorwic Quarry employed over 3000 men at its peak and many of these workers lived locally or caught the quarry train on the Padarn Railway to work each day. However, men from Anglesey, in particular, required to lodge or barrack at the quarry each week. They left home early on a Monday morning and returned on Saturday afternoon. Provisions for the week were carried on their journey. One of their homes for the week was the Anglesey Barracks high up in the quarry. The barracks consist of two identical blocks of 11 units facing each other across an unmade street. Each unit has a living room with a fireplace, and a bedroom, with space for four men. Amenities were few - no electricity, soft mattresses, toilets or running water, just basic furniture and little else. Windows were provided only onto the street. This way of life survived until 1948 when an unannounced visit by the local Public Health Inspector saw the barracks condemned as unfit for human habitation. After that the quarrymen from Anglesey travelled daily by bus. The one toilet for the whole barracks! We make our way to the top of the nearest incline At the winding house The twin tracks converge Double cable reels The smell of bearing grease is still very strong – perfume of the gods! The large brake lever Looking down the incline A workshop dating from 1938 Rock art overlooking the Electric Mountain A very steep incline in the distance (arrowed) Double bore tunnels sealed up A significant length of steel cable An access hole has been made through the base of this large incline Old trucks left Sleepers and a rail chair remain The trackbed is the only thing not covered by the slate Old rails used as support A rare stone sleeper A man on the road to the left gives scale to the size of this huge pit Slate in all its beauty Looking down on a blondin tower with Llyn Peris in the background. Notice the old telegraph pole to the right made from an old rail. Stanton Ben demonstrates the reverse method of getting down to it as the slate was very loose at this point and there is a huge drop off at the tower A handy ladder to get to the top for a photo Timber, iron, and lichen make a colourful combination From below The long drop is beyond the building From a distance the drop can be seen! After a very careful descent down the slate a point lever and set of rails come into view The trackbed has slid into the abyss below The rails are suspended in mid-air The blondin tower above Another classic drum winding house A very long brake lever for leverage to the right Ben demonstrates the lever action Not a lot left of the brake band on the right end of the drum The bearing grease has stood the test of time and was just as if had been applied that day A product of Llewellyn Wynn Williams 1896 of Railway Appliances Works, Cathcart, Glasgow. 1912 Patent for railway signal levers. 1925 Llewellyn Wynn Williams named as the proprietor of Llewellyn and Sons, Houghton Bridge Waggon Works, Greencroft, West Darlington. These rails lead to an old weigh-house Manufactured by Henry Pooley One of the company’s products Henry Pooley and Son was a renowned British mechanical engineering firm, founded in Liverpool in the late 18th century (c. 1790), that became a dominant manufacturer of weighing machines and industrial scales. Known for introducing railway weighbridges around 1835, they were a major supplier to railway companies and industrial sites before merging with W & T Avery in 1913. Not a lot left of this one A tight squeeze to get in here All the weight above is supported on old rusting rails A very, very long way down! Ben considers the way ahead They sure did build them close to the edge! Another blondin tower with adjacent ladder Railchairs still in situ in this tunnel We took the right one at this junction At the end was a room with a view Back outside and another points lever Two brick halves Adamantine bricks were high-quality, durable refractory bricks produced by Charles Davison & Co. Ltd at the Ewloe Barn and Old Ewloe works in Buckley, Flintshire (North Wales), active from the late 19th century until 1951. Often stamped "Industria Britannica," "Adamantine," and "Made in England" (despite being made in Wales), these hard, specialized bricks were used for industrial purposes. 'Adamantine' possibly holds the record for imprinting no less than 76 letters on one brick! Old Ewloe Brickworks, Buckley in the parish of Hawarden. The brickworks known locally as Davison's Top Yard, and Davison's Bottom Yard were Old Ewloe and Ewloe Barn Brickworks respectively. Etna Brickworks was taken over by Charles Davison who used the clay for his other works and Etna, near to Old Ewloe, was also called Davison's Top Yard. Charles was one of the promoters of the Buckley Railway Company. He opened his first works at Ewloe Barn about 1840 and subsequently the Old Ewloe Works in Etna Road in 1862 adjacent to John Royle & Co.'s Etna Works. Davison's company also acquired the nearby Globe Works. The business was then conducted successively under the Hurlbutts, the Steins, and The General Refactories. Ultimately, only Old Ewloe remained and was closed down during the 1970s. After complete demolition and clearance, the site was used as a council refuse dump. From about 1996 the whole area was transformed into The Etna Park and Heritage Trail. Buckley was the centre of Flint's brick industry with around 25 brickworks and home to some very well-known Welsh brands. The rails holding this lot up are buckling under the strain! An engine shed with pit Some more view of the wastelands at the spoil tips Trucks left behind Steel cables and rails from what once was The remains of two railway wagons can be seen at the bottom of this incline. These both provided a level surface on which the small quarry wagons could sit. The descent of laden quarry wagons on one of the large wagons hauled up the empty wagons on the adjacent track. They are steeper than they look Pulley with cable at the top The view down A lone wagon, twisted rails, and a points lever complete this scene of abandonment A wet day saw us back again for a short while until the driving rain and wind made photo opportunities difficult: A grey-looking Llyn Peris with the trackbed of the Padarn Railway above The access road to the Electric Mountain A very steep twin incline with the remains of the level surface railway wagons at the bottom The incline from a distance shows how steep it is They have the right idea A barren and grey landscape A lone photographer under his umbrella at the base of this mass of rock A lonely tree battles the elements Fully loaded trucks left behind when the quarry shut Discarded drive-wheels An old winding house in the foreground stands guard over the newer facility below This completes our look for now at this truly spectacular site. After four visits we have still not seen it all! It ranks as one of my all-time favourite explores. Many thanks to Stanton Ben whose suggestion to visit it, and his recces beforehand made for many memorable hours in his knowledgeable company. He is truly a slate guru! Out and About 2 A day at Duxford On the 29th April 2025 a group of us met at Epping station for a highly anticipated trip to the Imperial War Museum’s Duxford facility aboard a completely restored 59-year old, front-entrance Routemaster (BEA 2), looking splendid in its BEA livery. The regular commuters were confused when a non-red bus turned up! Glorious weather accompanied us throughout the day. We had a good high-speed run up to Duxford; the bus performed faultlessly and was very comfortable as we headed along the M11. On arrival the bus was driven on-site to be parked up next to BEA-liveried Hawker-Siddeley HS 121 Trident 2E G-AVFB, which dated from 1967 – just a year younger than our bus – for a unique photoshoot. Not since (or even during?) their working lives had they been pictured together. G-AVFB was built at Hatfield with three Rolls-Royce engines and was the second of 50 Trident 2 aircraft destined for BEA. It was the first airliner with fully automatic blind-landing equipment, able to land in all weathers, even in fog. She first flew on the 2nd November 1967 and was delivered to the airline on the 6th June 1968. Between March 1972 and May 1977, she was leased to Cyprus Airlines. Upon return, she was placed into storage until December 1977, when she went back into service with British Airways until March 1982. She was then stored at London Heathrow until entering preservation at IWM Duxford on the 13th June 1982. BEA 2 was the first BEA Routemaster to enter service between West London Air Terminal and London Heathrow airport in October 1966. It was one of 65 purchased by BEA but operated on its behalf by London Transport from Stamford Brook Garage. Every one of these buses was needed for the peak summer traffic. Approximately 30 of the original 65 survive to this day. BEA 2 was repainted in 1970 into the clockwork orange and white, and succumbed to British Airways’ blue and white corporate colours in 1973. The bus has been repainted in its original livery which it shares with BEA 1, also preserved. The opening of the Piccadilly Line extension to Heathrow and the relatively poor location of the West London Air Terminal ultimately spelt the end of the airport service, but BA found a willing buyer in LT as it wrestled with the engineering problems of the 1970s BEA 2 became RMA 14 and moved on to being used as an Aldenham staff bus based at Fulwell Garage and, ultimately, was transferred to Bus Engineering Ltd. This meant that BEA 2 avoided losing its staircase as others did on being converted into driver training buses; indeed, it managed to retain most of its original features. After a further sale to Green Rover near Watford, it gained RM blind boxes and was used until 1993. After that, it passed through several hands for preservation, before landing in 2019 with the current owners in the BEA2/RM5 Group. The restoration work started but soon coincided with the Covid lockdown. This was pretty terminal for any sense of budget or timescales to fulfil the ambition to restore the bus back to its original condition. That has now been achieved, with fine attention to detail. It is the intention to make BEA 2 available for the usual round of events in the bus preservation world. The only constraint has been working through all the mechanical issues which have surfaced on a bus which basically has not been used for 30 years; but they are pretty much there now. Viewed from the inside of a VC10 parked alongside This aircraft was operated by British Overseas Airways Corporation (BOAC) from 1965 to 1979 and is in the colours of BOAC-Cunard, a brief partnership between the airline and the shipping line. It also starred in the airline’s 1965 advertising campaign – “swift, silent, serene”. On retirement from passenger service, many VC10s served with the Royal Air Force as transports and tankers until 2013. A great rear end Inside we start with the mighty Tornado. This brought back memories as I worked on this when new at Warton. Panavia Tornado GR4 ZA469/029 was delivered here by road from RAF Marham, Norfolk. This is the second example of the Tornado ‘bomber’ on show here – Gulf War veteran GR1B ZA465 is resident in the AirSpace hangar. ZA469 at Blackpool Airport Fordson WOT1 6x4 Barrage Balloon Winch Truck This Messerschmitt Bf 109 E-3 crash-landed in Sussex during the Luftwaffe’s last major daylight raid on London in 1940. While on a bomber escort mission it was suddenly attacked over Eastbourne by Spitfires of 92 Squadron. When the engine failed the aircraft was belly-landed in a field. The pilot was taken into custody by the local Home Guard and police. His aircraft was sent on a tour of North America to raise funds for Britain’s war effort. The tail fin and engine are from a Heinkel He 111 E recovered from a frozen lake in Norway. The aircraft is believed to have landed there due to engine trouble during the German invasion of Norway in April 1940. Supermarine Spitfire Mk 1A This Spitfire was flown by Geoffrey Stephenson, commander of 19 Squadron when he was shot down over Dunkirk on 26th May 1940. Crash-landing on a beach near Calais he was captured and held as a prisoner-of-war until 1945. Hawker Hurricane Mk I V7497 This Hurricane flew against the Luftwaffe in late September 1940, serving with 501 Squadron. It was shot down over Kent whilst being flown by Pilot Officer Everett Rogers, who bailed out unhurt. Mikoyan-Gurevich MiG 21 This Soviet supersonic jet fighter entered service in 1959. It was designed to be faster than any other production fighter aircraft at the time. This aircraft was in service with the Hungarian Air Force. The Royal Anglian Regiment Memorial Second World War Fighter Pen The fighter pens were built to protect RAF aircraft from bomb blasts during the Battle of Britain in 1940. It was later used by the United States Army Air Force’s 78th Fighter Group, who were based here at Duxford from 1943-1945. To protect the fighters, twelve pens were built on three sides of the airfield. Each pen could accommodate two aircraft, so 24 fighters could be sheltered in total. The pens were often placed near areas of natural camouflage, such as hedges or, in the case of this one, a line of trees, to make them more difficult to spot from the air. Two pilots chatting on top of a fighter pen at Duxford, which is protecting a Hawker Typhoon Mk. IB of 181 Squadron, late 1942 Plenty of military kit on show Bristol Bloodhound Mk 2 This anti-aircraft guided missile was part of Britain’s air defence system from 1958 to 1991. This one came from No 85 Squadron at RAF West Raynham in Norfolk. German Tiger 1 Heavy Tank Soviet T34/85 Medium Tank Soviet Josef Stalin 2M Heavy Tank PLUTO Pump (Pipe Line Under The Ocean) PLUTO was laid across the English Channel to provide the Allied armies with the fuel vital to sustain their offensive. Pumps were used at a series of relay stations to maintain a constant pressure and flow of fuel. German Jagdpanther tank destroyer Although only 382 were built, the ‘hunting panther’ was the most successful German tank destroyer of the Second World War. This example was a command version with provision for extra radios. The rippled plaster coating was applied for protection against anti-tank mines. It was knocked out by Allied gunfire in North-West Europe and brought to England for evaluation by the British Army at Chertsey. Bedford OYD This British 3 ton 4x2 general service truck was used until the 1960s. One of the most common British vehicles of the Second World War, 72,385 were built before 1945. Thornycroft Antar Tank Transporter Originally developed as a private venture the Antar was, with modifications, adopted by the British Army in the 1950s. They replaced wartime units and served until the mid-1980s. Centurion Tank Mark 3 The Centurion was the first British post-war battle tank. It first saw action in the Korean War and has since proved itself to be one of the best tanks ever built, serving around the world. International Harvester M386 TEL This American Tractor, Erector, Launcher (TEL) vehicle, based on the M54 5ton truck series, was used to operate the Honest John missile. Thirty-six were in service with the British Army from 1961 to 1982. The Honest John nuclear missile was in service with US and British armies from 1953 to 1974. It is an unguided rocket fired form the mobile launcher. With a range of up to 23 miles its purpose was to destroy areas in the rear of the enemy front line. GKN Saxon (Internal Security Patrol Vehicle) Developed by GKN the Saxon ‘battlefield taxi’ armoured personnel carrier Patrol was an upgraded variant used for counter-insurgency operations. This one served in Afghanistan during 2007-2010. This internal railway line is a 60cm narrow-gauge trench railway system. It was established to demonstrate the light railways used during the First World War to transport troops and ammunition. The line operated for a short period in the early 1990s (around 1992), featuring two Motor Rail locomotives and coaches in a "top-and-tailed" arrangement. The track originally featured a loop at the western end of the airfield and a spur running into the Land Warfare Hall. The line is no longer operational, having ceased operation over 25 years ago due to issues with running near taxiways and the construction of a fuel storage complex over part of the track. Some track remains in-situ, particularly around the Land Warfare Hall area. The museum holds War Department Light Railway (WDLR) equipment, including a protected 40HP Motor Rail (LR3085) and a 20hp Motor Rail. There was previously a plan to run a Baldwin 4-6-0T steam locomotive on the line, but it was never realized, and the locomotive was later transferred to the Welsh Highland Heritage Railway. The Land Warfare Hall, where the railway equipment is displayed, has been subject to closure and redevelopment, leaving the future of these specific rail exhibits in question. The American Air Museum at IWM Duxford stands as a memorial to the 30,000 members of the US Army Air Forces who died while flying from Britain during the Second World War. It tells the story of the people - from civilian to Private to President - whose lives were shaped by their experiences of conflict from the First World War right up to the present day. The American Air Museum is also home to the biggest collection of American military aircraft on public display outside the United States. In reality this is 43-31171 but is on display at the IWM Duxford to represent B-25J 43-4064 that served with the 488th BS, 340th BG, 12th Air Force in the latter stages of the Second World War from its base in Corsica. This was the BG that formed the inspiration for Joseph Heller's satirical novel Catch-22. Heller served as a bombardier in the 488th Bomb Squadron and had extensive experience flying bombing missions in Mitchells. Boeing B-52D Stratofortress American strategic bomber military aircraft, built by Boeing Airplane Company in 1957 and used by Strategic Air Command (SAC), United States Air Force (USAF) on over 200 missions from 1957-1983. Completed 14,000 flying hours during its service including flying 24 hour nuclear alert missions from 1957-1966, and periodic duties in South-East Asia during the Vietnam War from 1966-1978. This included flights on Operation Arc Light close air support missions, on strategic operations against North Vietnam, Operation Linebacker (May -December 1972) and Operation Linebacker II (December 1972). General Dynamics F-111E A veteran of Operation Desert Storm. Many F-111E’s were operated by the 20th Tactical Fighter Wing (TFW) at RAF Upper Heyford in the UK from 1970 until 1993. The 20th TFW conducted numerous training exercises during the Cold War and stood ready to go into bat for NATO against the Soviets and the Warsaw Pact nations. Fortunately, it was never required in this role but 20th TFW F-111E’s acted as an airborne reserve in 1986 to F-111F bombers during Operation El Dorado Canyon airstrikes against Libya. Over the years a number of F-111E received upgraded avionics and engines. The type also saw service during the Gulf War from 1990 to 1991 and the last were retired from the USAF inventory in 1995. This particular F-111E (67-012) was the last operated by the 20th TFW at Upper Heyford. Lockheed SR-71A Blackbird The Lockheed SR-71 Blackbird is the highest-flying and fastest military jet aircraft in history. The SR-71 Blackbird at IWM Duxford has flown higher than any other. It set the world record for sustained altitude flight in 1976, flying at 85,000 feet. Blackbird was developed in the 1960s as a high-flying Cold War reconnaissance jet. It is still considered by many as the most advanced aircraft of its type, flying at three times the speed of sound, faster than any weapon that could be fired at it. Boeing B-29A Superfortress A former United States Air Force B-29A, it was recovered from the China Lake range in 1979, restored to flying condition as G-BHDK and flown across the Atlantic to Duxford, arriving in March 1980. Painted as 461748 to represent an aircraft of the 501st Bomb Group United States Army Air Forces and named 'It's Hawg Wild'. On loan from the United States Navy. 9.2 inch Coastal Defence Gun Originally installed at the Spur Battery in Gibraltar during 1902, this gun was typical of those used across the British Empire to protect strategically important coastal sites. The Battery was 1,130ft above sea level and 250ft below the top of the Gibraltar Rock. It was used in action during the First World War when it took part in the bombardment of German Submarines spotted off the coast on 31st December 1915. The barrel was replaced in 1929 and in 1935 it was converted from a Mk5 to a Mk7, with increased armour and updated control systems. It was last fired in 1973 when 29 rounds were fired at a towed target, which received several direct hits. Replaced by an Exocet guided missile system, it was dismantled by Royal Engineers and installed at Duxford during 1982. A very good day here with more to see but BEA2 is awaiting our high-speed return trip! Next time: “Rivals Reunited” Some beauties from the Driffield show

- 1 reply

-

11

-